This Greener Tech Bite reviews machine adjustments and sealing jaw designs that provide the pressure and heat* required for quality seals. You can consult additional, detailed posts and videos on each topic by clicking the red links or the corresponding images.

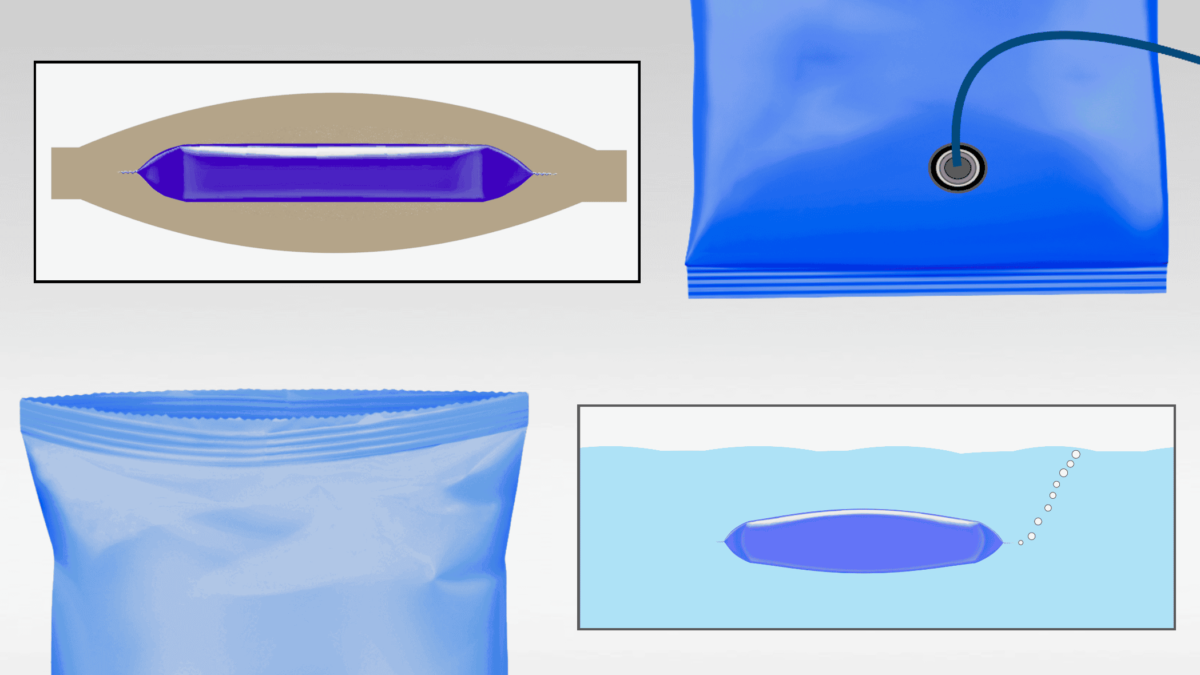

Quality seals on flow wrappers & vertical baggers require a combination of time, pressure, and heat, if utilized, that seals across varying thicknesses created by the fin or lap seal, gussets, or other pleats and wrinkles.

With time typically limited by high line speeds, your effective operating range for pressure and heat may be narrow and difficult to maintain. Too little leaves seals open or leaking; too much will split, distort, or damage the seal.

Adjustments

Product Feed & Package Formation

It’s important to consider your full packaging process. Adjustments to product feed and package formation can reduce variations in the size and location of the fin seal, lap seal, or gussets and eliminate extra wrinkles and folds that reduce seal quality.

(Click on the red links or images for detailed posts & videos on each topic.)

Flow Wrapper adjustments include product feed, film alignment and tension, and fin seal formation.

Vertical Bagger adjustments include product flow, roller position, and film drive. Former design and condition are also crucial.

Sealing

Carbon Impressions – Visual inspection of packages and leaker tests indicate problems with pressure or heat, but they don’t tell the full story. Carbon impressions reveal important but less obvious issues such as misaligned serrations, uneven pressure, jaw wear, and product contamination. Make carbon impressions part of your preventative maintenance program.

Knives and Anvils – On machines with rotary jaws, worn and incorrectly adjusted knives and anvils are often overlooked as a cause of leakers, damage, and other sealing problems.

Clearance and Pressure are critical adjustments on flow wrappers. But their differences, and when each should be adjusted, are not always clear.

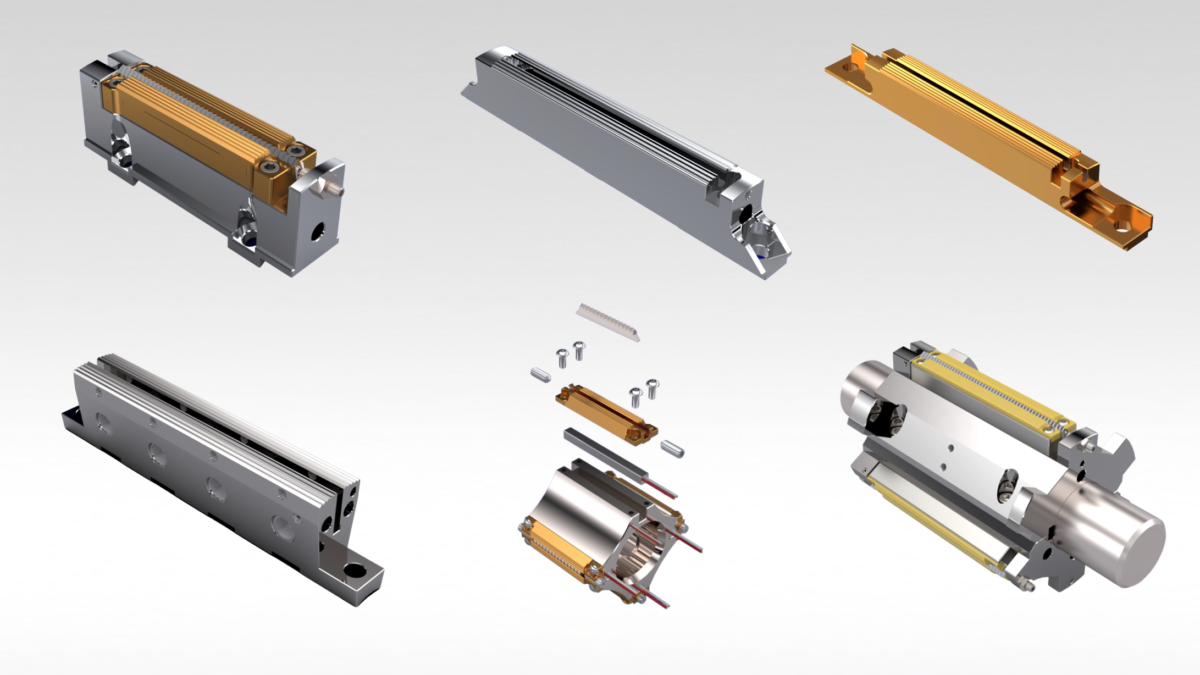

Sealing Jaw Design

Sealing jaw designs are not universal; your jaws should be custom designed for your film, product, machinery, and running conditions.

(Click on the red links or images for detailed posts & videos on each topic.)

Serrations

The serration profile must transfer consistent pressure and heat across varying thicknesses of film.

Special Features

Special features may be required, such as:

Easy Seal™ FLEX sealing faces to seal across the fin seal.

Design Solutions

This case study demonstrates the benefits of properly designed sealing jaws.

Standardization

Do your results vary across different shifts, makes and models of machinery, packaging lines, or locations? You can produce consistent quality seals by establishing standard adjustment procedures, providing training, and by standardizing former and sealing jaw designs.

(Click on the red links or images for detailed posts & videos on each topic.)

If you need recommendations for machine adjustments and sealing jaw designs that optimize pressure, heat, and seal quality, contact Greener Corporation. We develop and deliver full process solutions, worldwide.