The ultimate quality of the packages produced on horizontal flow wrappers requires a complex series of events to form and fill each package and move it through the packaging process. In the following post and “Tech Bites” video we explore the many steps that occur before and after packages are cut and sealed—from the product feed and film unwind through to the discharge belt—that must be fine-tuned to optimize seal integrity, package appearance, and productivity.

Film Roll Alignment

- Center the film roll side to side so that the edges of the fin seal meet evenly and create a clean, parallel edge.

Film Tension

- If the film wanders off center, check to make sure the film is making enough surface contact with the pivot rollers so that the resulting tension keeps it aligned side to side.

- Adjust the spring tension and the angle at which the film enters the forming box so that the film tracks smoothly and evenly. Too much or too little tension can cause wrinkles and irregularities in the package.

Forming Box

- The forming box should be correctly designed and adjusted for the product and film in use.

- For products that are variable in size, make sure that the former size accommodates the largest possible product.

Product Centered Side-to-Side in Package

- Adjust the product rails on the infeed so that as they guide the product into the forming box the film tube forms evenly around it, without excess space on either side.

- In most applications the product, forming box, fin wheels, and the sealing and cutting head should all align on the same centerline.

Product Centered End-to-End In Package

- Each product portion should sit against the flight pin as it is pushed into the forming box.

- For the best results, the distance between the flight pins should correspond with the package length, and the film speed should be synchronized with the product speed.

- Make adjustments so that the product is inserted as far into the forming box as possible.

- Product that is too far forward or back in the film tube can be damaged by the crimpers and can contaminate the end seal.

Deck Plates

- Deck plates that are not level and smooth can inhibit the movement of the film and the product.

- Exercise care when removing and reinstalling deck plates—they can be easily bent or otherwise damaged.

- Avoid using screws that protrude and inhibit package movement.

Fin Wheels

For optimal performance of the fin wheels, which draw the film through the former and create the fin seal, make sure that:

- Their speed corresponds with the product feed and the film feed rates.

- They apply enough pressure to draw and seal the film properly, but not so much that they cut thought the film.

- Their serration pattern is correctly designed for the film in use. In some cases a different pattern on each pair of fin seals is required to draw and seal properly.

- The sealing faces are not worn, damaged, or contaminated with product.

- Temperature settings (if applicable) are not too high. Excess heat can distort the film and cause film slippage.

Vacuum

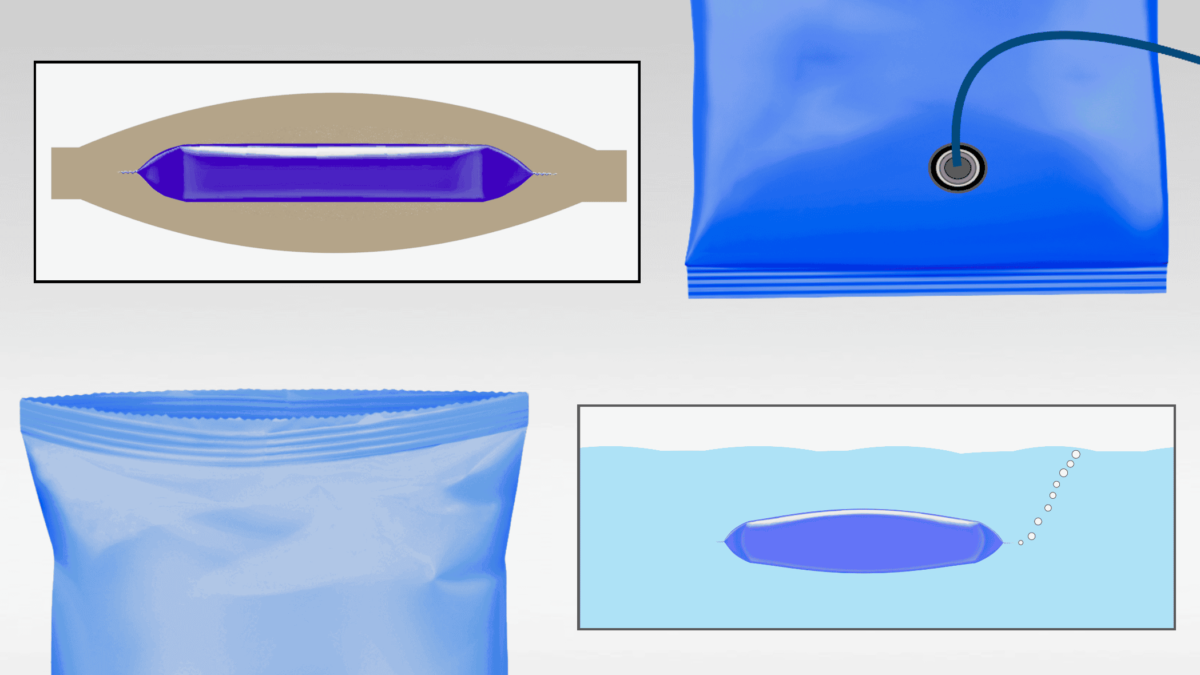

If vacuum pressure is used, adjust it to properly remove air from the package without creating wrinkles and pleats that can cause channel leakers in the end seal.

Fin Seal Fold

Make sure that the fin folder wheels or other folding mechanism consistently fold the fin seal so that it will lie flat against the package. Irregularities in this process create wrinkles and creases in the fin seal that degrade package appearance and cause leakers at the end seal.

Tuckers and Gusseters

If your package requires the use of tuckers and gusseters, adjust them so that the extra layers of film they create at the end seal are as consistent in size and location as possible. Make sure that your crimpers are designed and set up according to these specifications to provide optimal sealing pressure and heat transfer (if applicable).

Cutting and Sealing Head

Packages should maintain speed and remain on the same horizontal plane as they move from the infeed deck plate, through the cutting and sealing head, and to the discharge belt. Impediments and alterations to this flow create distortions and pleats in the film that degrade package appearance and can cause end seal leakers.

Vertical Alignment

- Adjust the cutting and sealing head vertically so that the crimpers come together midway between the top and bottom of the package, keeping it on the same horizontal plane.

- When packages get pulled upward or downward by the crimpers they are more likely to develop wrinkles and creases, which degrade package appearance and can cause end seal leakers.

Product Carriers

- Make sure the product carriers, mounted on the lower crimper shaft, are correctly sized so that they maintain the package along the same horizontal plane as it moves through the cutting and sealing head.

Package Discharge

- Adjust package discharge guides such as brushes, belts, and rollers so that they do not impede the movement of packages as they exit the sealing and cutting head.

Pause / Dwell

- To ensure proper presentation of the film tube and product to the sealing and cutting head, adjust the end seal pause, or dwell, so that the crimpers move at the same or at a slightly faster speed than the film.

Additional Resources

Please click on the links below for more information:

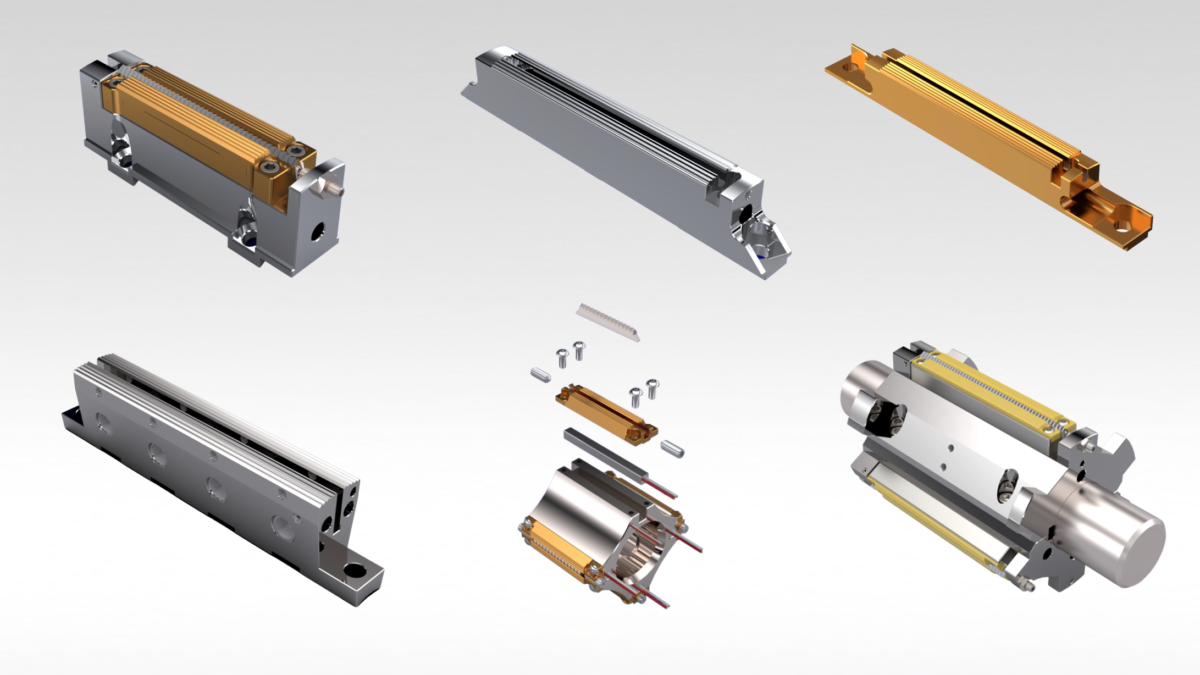

- Sealing Over Multiple Layers of Film at the End Seal – Optimizing Crimper Design

- Cleaning to Improve Package Quality and Productivity

- Contact Greener Corporation about solutions designed to meet the specific needs of your packaging operation, including Problem Resolution, Training, and Project Development.