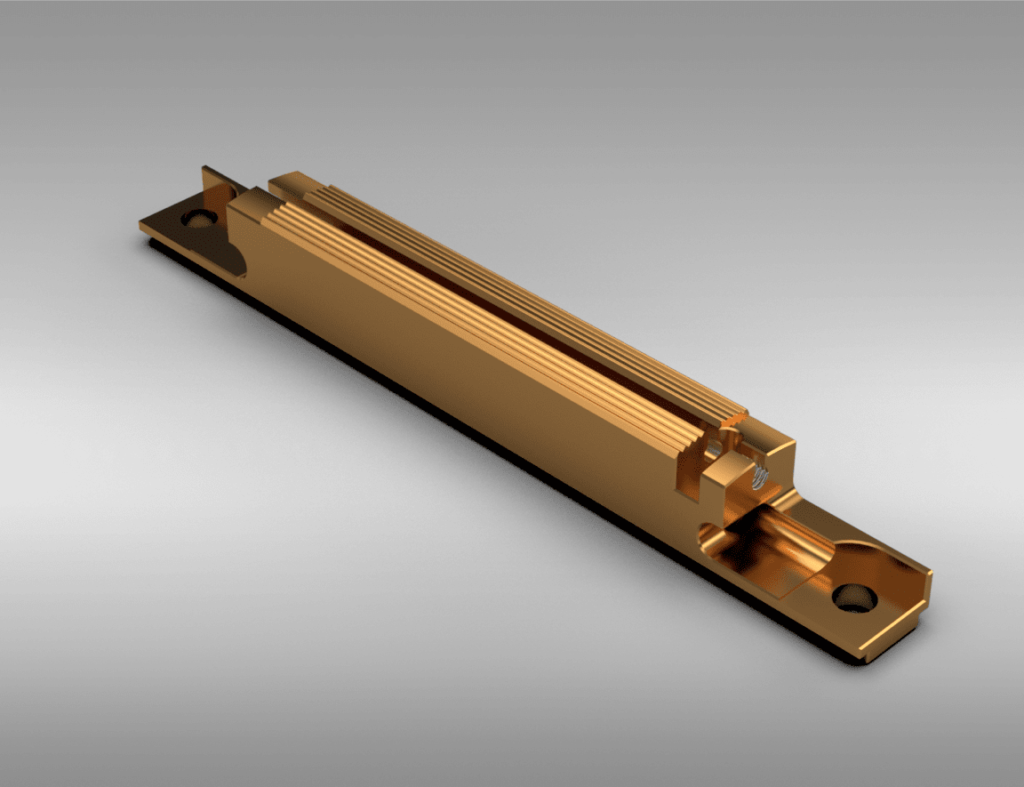

Sealing Jaws for Horizontal Flow Wrappers

Sealing jaws are not standardized, universal components. When you work with Greener Corporation, we integrate the unique variables of your packaging operation to design and manufacture sealing jaws that help you optimize set-up and your machine environment.

We incorporate your machinery design and condition, product, packaging material, seal integrity requirements, line speeds, and other operating conditions to optimize sealing jaw performance.

Sealing Jaws Design Options

Serration Patterns

Greener can match the current specifications of your sealing jaw serration pattern or recommend a different serration geometry to meet the requirements of your packaging operation. Our specialized CNC grinding machinery enables us to custom design or match virtually any tooth profile.

Special Design Features

- Easy Seal™

- QUICK-CHANGE Inserts

- FLEX or SOLID Sealing Face

- Seal Reduction Profile (pdf)

- Fracture Elimination Design (FRED) (pdf)

- Hole Punch

- Special Platings and Coatings (pdf)

- Drum and Clamp Style Sealing Jaws (pdf)

Custom Designs

Our Project Development experts will help you create custom crimper designs for many types of packaging projects such as new film qualifications, changes in package size, and cross-platform crimper standardization.

Sealing Jaw Materials

Greener will recommend specialized materials to optimize performance or to provide other desired functional characteristics that are not available with basic steel jaws.

High Durability Stainless Steel

- Provides excellent resistance to sealing face wear and damage

- Prevents rust and corrosion without the need for plating

Dura-Therm

- Provides exceptional heat transfer and thermal consistency across the sealing face

- Prevents corrosion without the need for plating

- Provides a flexible, durable sealing face on Easy Seal™ Dura-Therm FLEX Jaws

Kevlar® Composite

- Provides a flexible, resilient sealing face on Easy Seal™ Jaw inserts for cold seal applications.