Changes on horizontal flow wrappers occur regularly—during sanitation, product changeovers, part installations and adjustments, maintenance, and from wear and tear. These changes can impact the success of your next production run, yet they often go unnoticed.

This Greener Tech Bite presents our quick, Preventative Maintenance Checklist. By investing five or ten minutes to inspect these four areas before starting production, you will be up and running more quickly and avoid hours of downtime.

It’s easy to underestimate the value of these inspections, or to skip them when time seems too tight. But even details that may seem insignificant, such as a protruding screw in a deck plate, can cause problems.

Not everything you discover will require immediate action. But you’ll be able to track conditions such as backlash or jaw wear and know when its time to correct them—before they degrade package quality and disrupt production. When urgent problems do occur, you can compare current conditions with previous inspection results to recognize what has changed and resolve the issue.

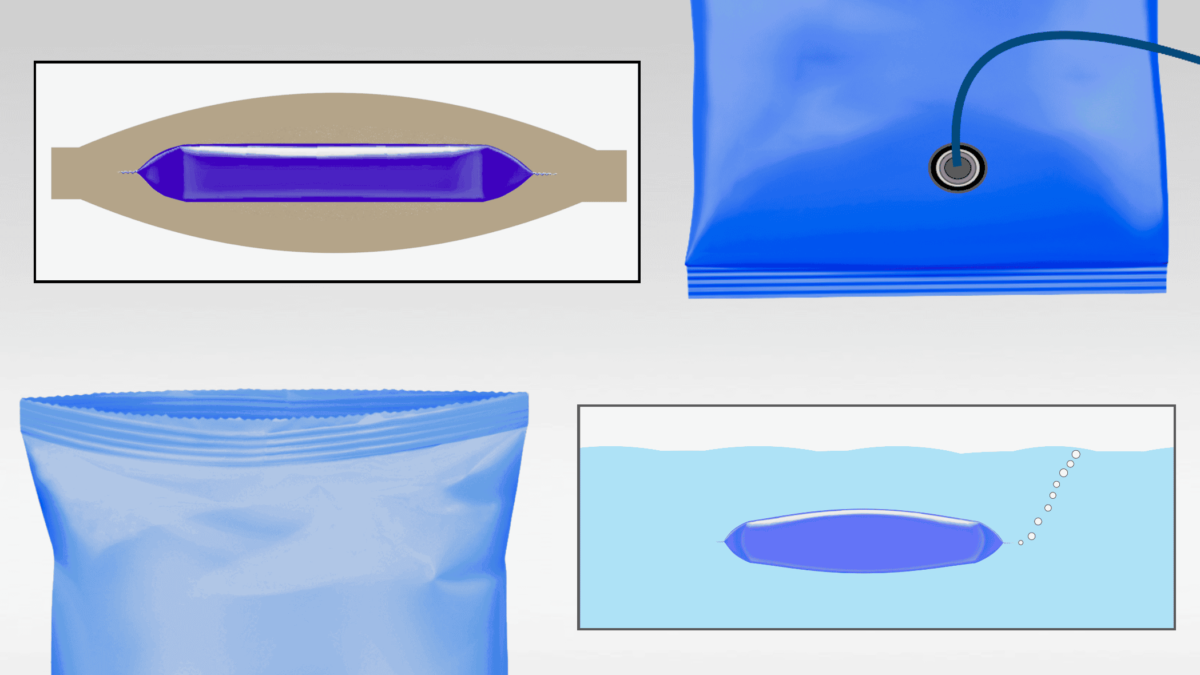

1. Package Formation

Begin by checking the Package Formation components. Small, seemingly insignificant variations here can create wrinkles, pleats, and other deformities that cause leakers and other problems.

2. Controller

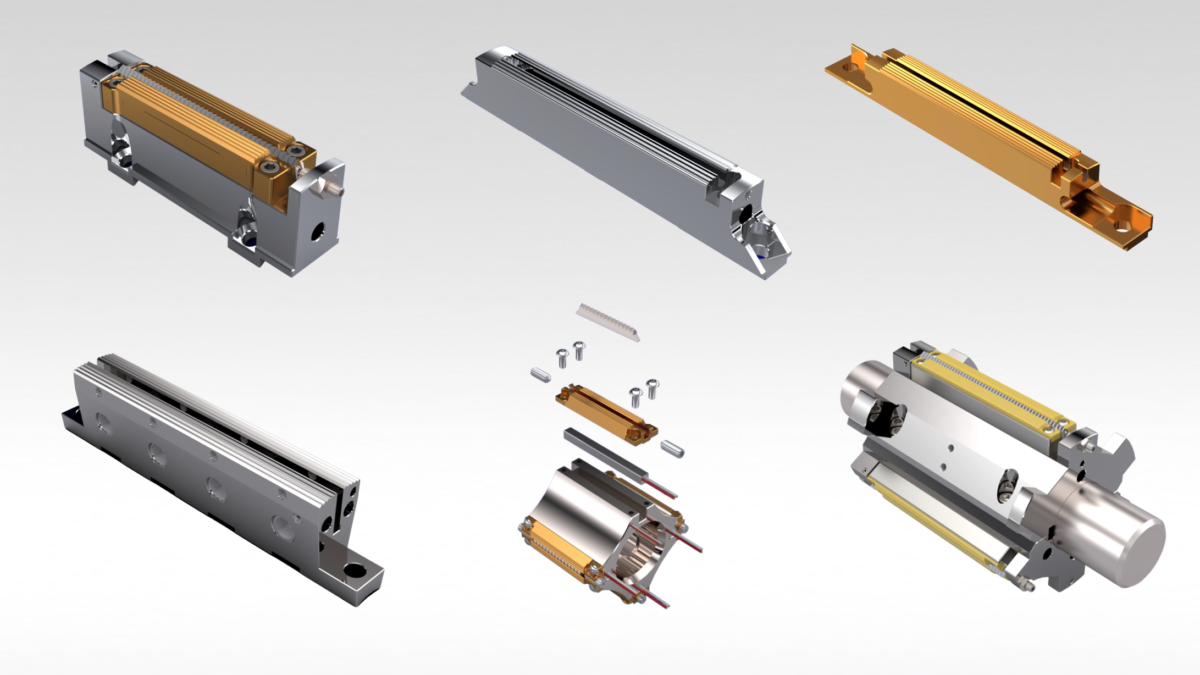

3. Sealing Jaws

4. Cutting and Sealing

Lastly, inspect the Cutting and Sealing process. Even without product, you can check the basics. Mount the packaging material roll and run some film through the head.

When you perform regular Preventative Maintenance Inspections, you’ll have time to make corrective adjustments before you are under the stress of production. Once product comes down the line, you will get up and running more quickly, with less scrap. And you’ll be able to keep running, with fewer problems and less downtime.

For more technical resources browse additional posts and videos and contact Greener Corporation. We develop and deliver Full Process Solutions, worldwide.