This “Tech Bites” video and blog post from Greener Corporation explains how carbon paper can help you optimize seal quality on horizontal wrappers and vertical baggers.

Crimpers and sealing jaws that are worn, damaged, or need a good cleaning, as well as imbalances in alignment and pressure adjustments, can cause channel leakers and distorted end seals. Whether executing an initial set-up or troubleshooting during production, carbon paper impressions can reveal issues that are not otherwise apparent and help you make the adjustments needed to produce consistent quality packages. We find that “carbonless” paper (also called NCR paper) without lines or printing provides the best results.

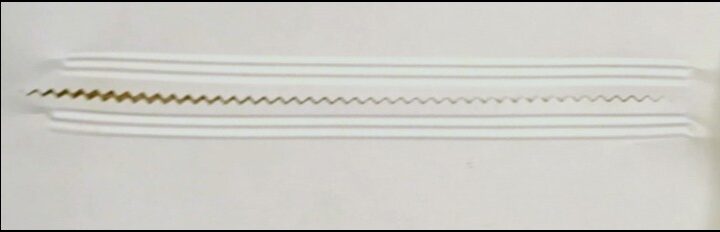

In this impression, made with plain copy paper, the crimpers appear to be well aligned, balanced, and in good condition:

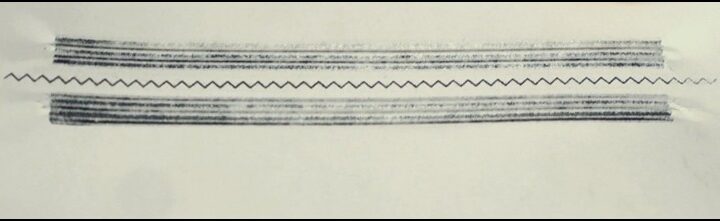

A second impression, made on carbonless paper, reveals more details—the crimpers are exerting slightly greater pressure on the left than on the right:

While this difference may seem slight, its effect can be magnified by the limited dwell time and heat transfer (if applicable) at production speeds. Some fine-tuning of alignment and pressure at initial set-up will improve package quality and productivity, and help alleviate the need for readjustments and downtime later on.

When problems do arise during a production run, a quick check with carbonless paper can help you diagnose the problem. In one case packages were produced with consistent channel leakers; an impression revealed that excess crimper wear—previously unnoticed—was causing the problem.

The need for diagnostic help may seem most prevalent on horizontal flow wrappers, but we find that improperly aligned sealing jaws are also a frequent source of poor package quality on vertical baggers. With either style machine, a detailed, carbonless paper impression yields valuable feedback.

Carbonless paper, which can be found at office supply stores or obtained from Greener Corporation, should be a standard fixture in your toolbox and play a regular part in your training exercises and procedures. Use it often to optimize seal quality and reduce downtime.

To Learn More Click Below:

• Cleaning to Improve Package Quality and Productivity.

• Clearance and Pressure on Horizontal Wrappers: What’s the Difference?

• Training Programs with Greener Corporation.