One of Greener’s Technical Salespeople discovered that knife purchases by their customer had grown by 35% over the past year, at an additional cost of nearly $10,000. It seemed unlikely that additional production had accounted for all of this increase, which indicated to him that the customer could be experiencing problems on their horizontal flow wrappers.

He contacted the maintenance and production managers at the customer and asked about potential causes for the significant increase in knife usage. They reported that:

• No additional flow wrappers or shifts had been added; production levels remained the same.

• The packaging material had not changed.

• Cutting and sealing problems, however, had become a consistent cause of downtime over the past year. They had experienced higher than normal staff turnover, and their newer mechanics and operators were still learning how to set up and maintain the flow wrappers.

We suggested a comprehensive line evaluation to find the root causes of these issues and develop long-term solutions. The customer agreed, and scheduled Greener to conduct the evaluation.

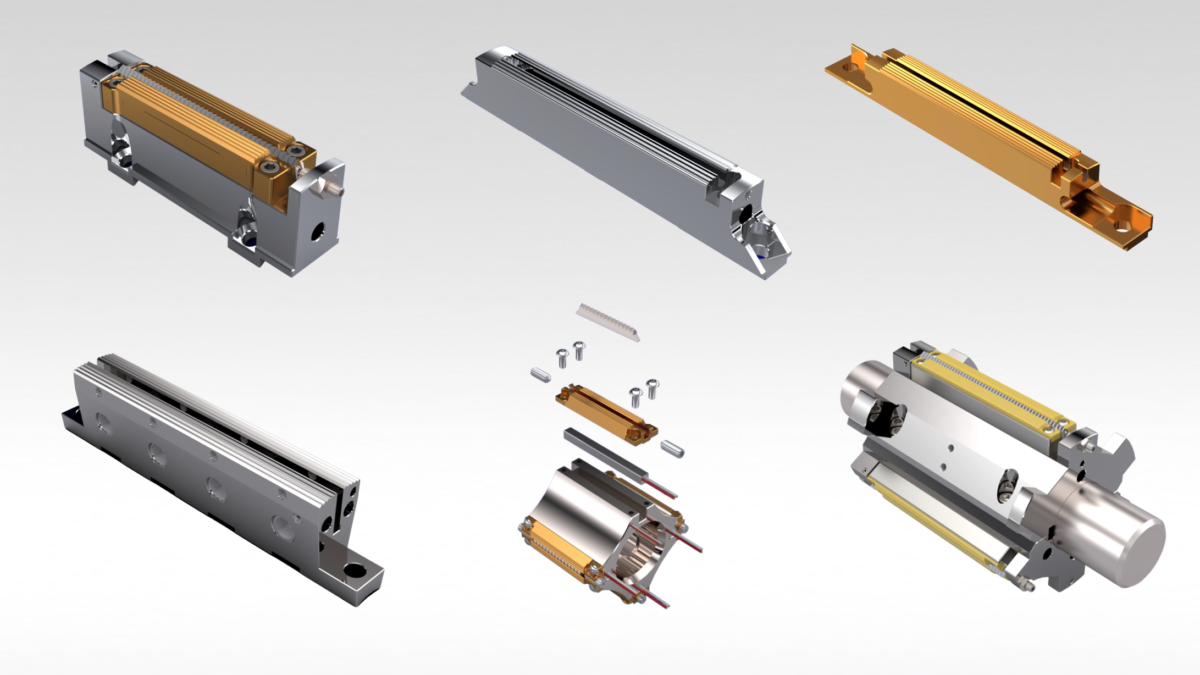

When one of Greener’s technical service experts walked onto the customer’s packaging floor a few weeks later, he heard the repeated, heavy impact of knives striking against anvils.

Further investigation revealed the likely reason for this over-adjustment. In an effort to minimize downtime during production, mechanics were replacing worn knives without changing the anvil. New knives had to strike the anvil with great force in order to cut across the impression made by the previous knife.

At first changing just the knife had been a limited, emergency measure to keep a machine running until the end of a production run. But over the past year this had become a standard practice. The ultimate result was higher knife costs and increased downtime to address cutting and sealing problems.

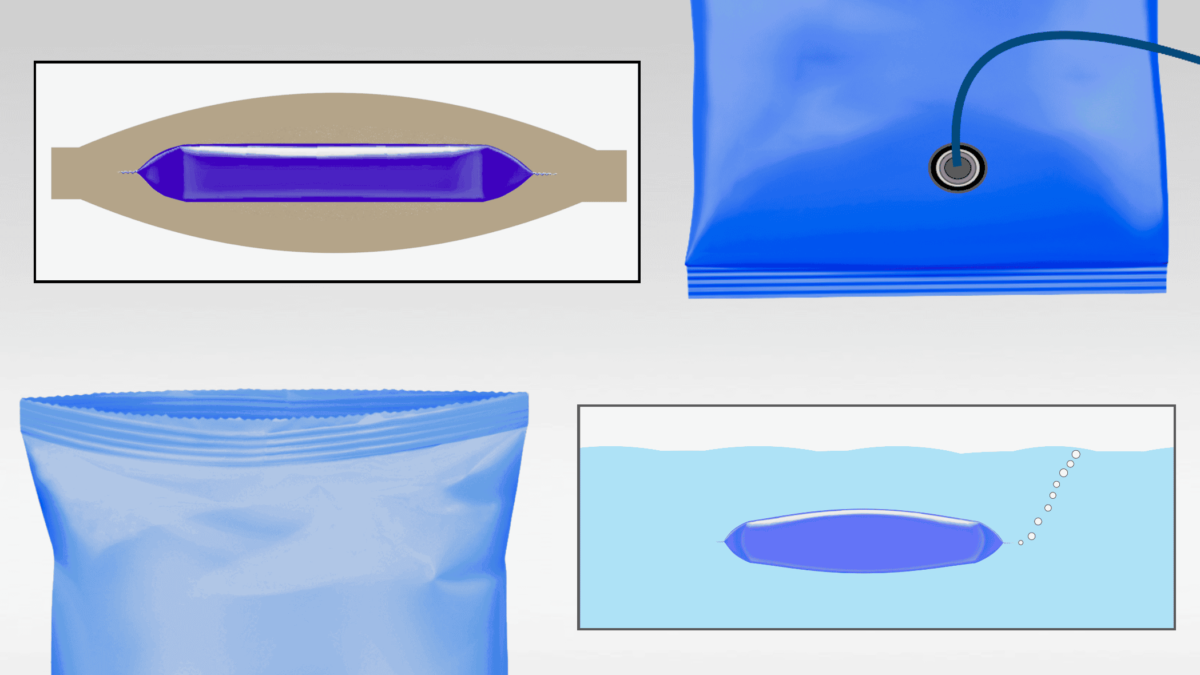

The line evaluation also revealed that leakers usually occurred on the leading seal of the package. Based on the cutting issues this made sense. The force generated when an over-adjusted knife strikes the anvil pushes the sealing jaws apart and can prevent the serrations from transferring adequate sealing pressure and heat.

A trial was run on one wrapper where both new knives and anvils were installed. Cutting occurred more silently, without excess pressure, and the chronic seal quality issues were eliminated.

As we developed a plan with the customer to consistently replicate these improvements on the whole packaging line, another recent change was identified. With the intention to save time and increase package quality, machine operators had been empowered to make small wrapper adjustments that had previously required a mechanic. But with many new and inexperienced operators, these adjustments were often ineffective.

The maintenance and plant managers realized that they needed to create and implement standard operating procedures. They asked Greener to help establish these standards and to provide training.

Our technical expert returned and conducted classroom and hands-on training programs for packaging machine operators and mechanics on all shifts.

The better informed and well-trained staff quickly produced tangible results:

• Knife usage and costs returned to previous levels.

• Downtime was significantly reduced.

• Both seal integrity and package appearance now far exceeded minimum quality standards.

To learn how line evaluations and training can help you improve your packaging process on flow wrappers and vertical FFS baggers, contact Greener Corporation.

We develop and deliver full process solutions, worldwide.