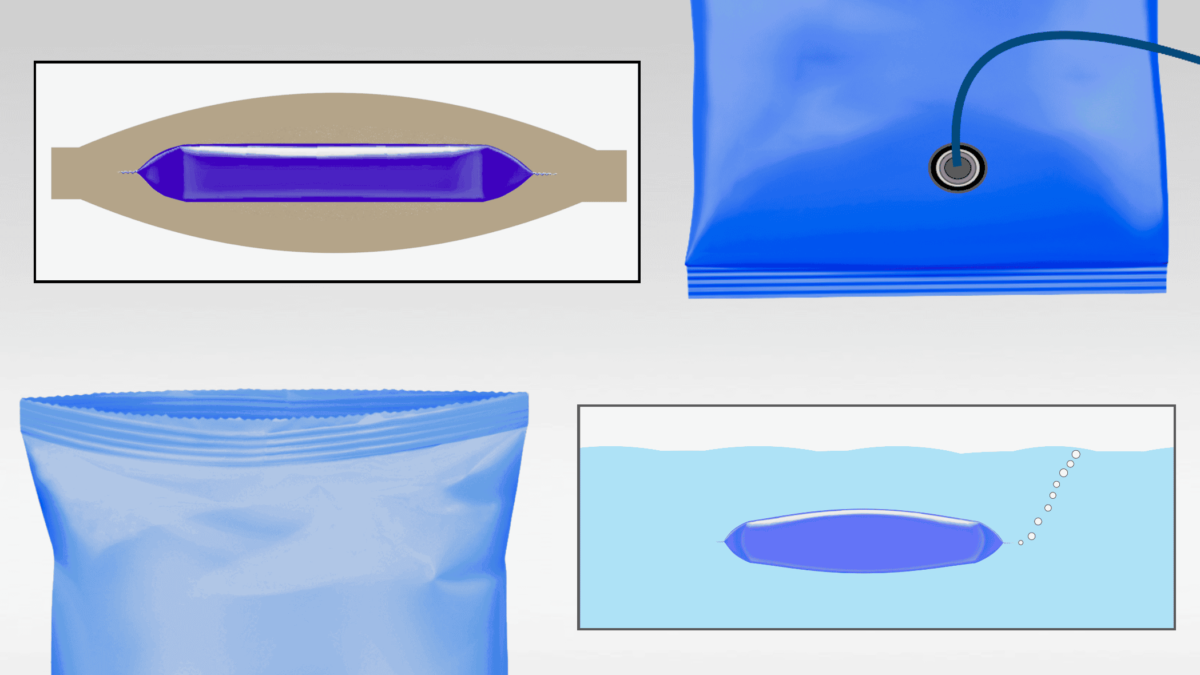

Carbon impressions are a vital diagnostic tool for setting up sealing jaws on flow wrappers. This Greener Tech Bite reviews nine carbon impressions that illustrate some common misadjustments.

With an accurate setup, your carbon impression will be uniform and consistent over the peaks and valleys of each serration, across the length of the sealing jaws, and on both seals.

1. Phasing Between Shafts Not Synchronized – Horizontal Serrations

On our first example, the impression is consistent from end to end and on both sides of the slot, but uneven over the peaks and valleys of each serration.

The dark, horizontal lines indicate that the serrations are hitting side to side and not meshing together evenly.

In this case we can rule out improper mounting of the sealing jaws as a cause of the misalignment, since on this wrapper the jaws fit into slots on the shaft that align them on the centerline.

Here the phasing, or timing, between the upper and lower shafts is not synchronized and needs to be readjusted so that the serrations are properly aligned.

2. Phasing Between Shafts Not Synchronized – Vertical Serrations

Our second carbon impression also indicates misadjusted phasing, but for sealing jaws with vertical serrations. The upper seal is weaker, a bit narrower, and has a row of sharp dots along the slot.

When phasing is out the knife and anvil slots may not line up. The dots were created when the crowns of the serrations on the upper jaw struck the anvil, which had been installed in the lower jaw.

The serrations here are also slightly misaligned—they hit harder on one side of each serration and leave a less uniform impression.

3. Severe Misalignment – Vertical Serrations

On this next example, severely misaligned vertical serrations only make narrow contact with each other and leave an impression of dark, well defined lines.

4. Clearance Not Parallel

Carbon impression four is lighter on the left end and darker on the right, indicating that the clearance between the shafts is not parallel and needs a slight adjustment.

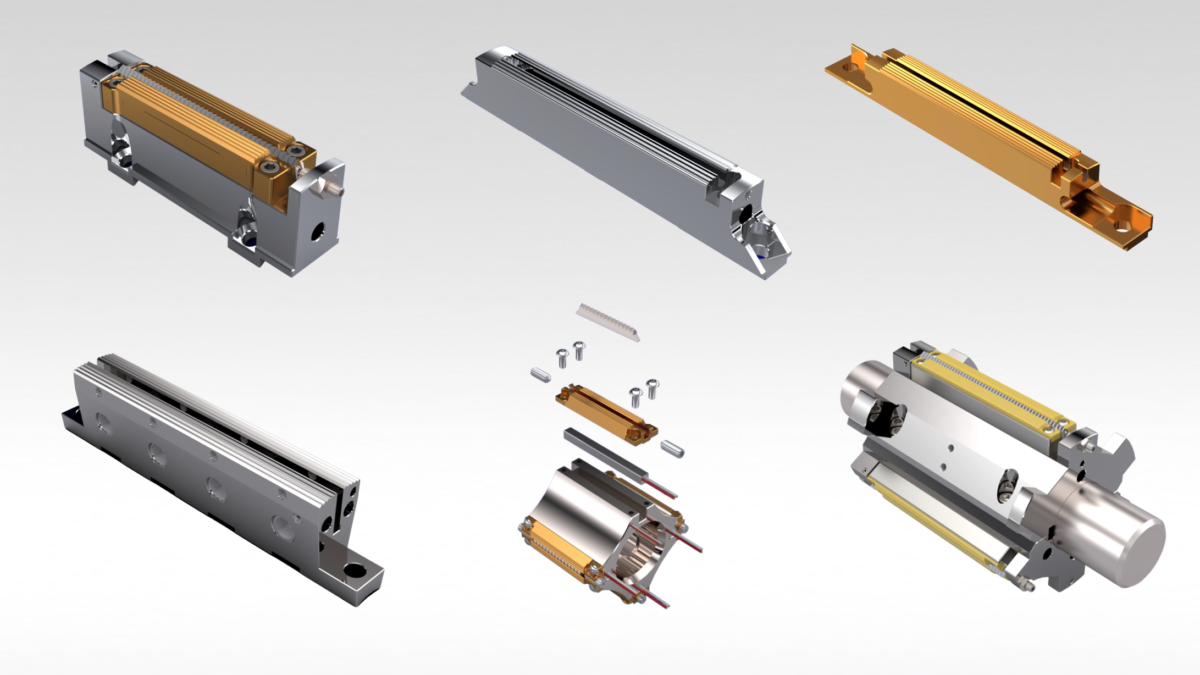

Sealing Jaws Mounted on Flat Shafts

These next carbon impressions were made with sealing jaws that mount on a flat shaft surface, without a key, slot, or a radius that would align them with the centerline of the shaft.

5. Serrations Diagonally Misaligned

On this carbon, notice how the impression changes from one end to the other.

The dark, horizontal lines show that the serrations are not fully meshing and are hitting each other on opposite sides. From left to right on this view, the serrations hit harder on the bottom side, produce a faint impression in the middle, and hit harder on the upper side.

The sealing jaws are diagonally misaligned to each other and should be readjusted so that the serrations are parallel.

6. Serrations Diagonally Misaligned – Less Severe

This next example displays less severe diagonal misalignment; the impression is lighter on the upper left and lower right, and darker on the lower left and upper right.

7. Sealing Jaws Offset from Centerline of Shafts – Horizontal Serrations

Impression seven shows a readily noticeable misadjustment; the seal on one side of the slot is significantly narrower and weaker than the other side.

Here the knife and anvil slots and the serrations are aligned, but the pair of sealing jaws is offset from the center line of the shafts.

Since the radius of the sealing face doesn’t align with the radius that the jaws are rotating on, there is a gap between the serrations on one seal and the impression is narrower and weaker.

8. Sealing Jaws Offset from Centerline of Shafts – Vertical Serrations

When sealing jaws with vertical serrations are offset from the centerline, the seal widths on a carbon impression are often more consistent. But, as this example shows, the impression of one seal will still be weaker than the other.

9. Serrations Offset

On this last carbon impression the seal width on one side of the slot is also narrower and weaker—but here the cause is different.

In this case the sealing jaws are misaligned with each other by a full serration and the slots don’t line up.

The effective width of each sealing face is reduced and, since the working radii of the sealing jaws are offset, the seal on one side receives less pressure and is weaker and narrower.

Carbon impressions often indicate multiple setup issues and can be challenging to interpret. If you’d like help with diagnosing your impressions and developing solutions, contact Greener Corporation.

We provide integrated parts and technical services worldwide.