This Greener Tech Bite is the first in a series of case studies on the Package Diagnostic Process.

When we work with clients, sample packages provide vital diagnostic clues for troubleshooting problems on flow wrappers or vertical baggers. And even when clients don’t report problems, we use sample packages to help them discover and implement improvements that they may have overlooked—from new knife, sealing jaw, and former designs to machine adjustments that optimize the whole packaging process.

Diagnosis

Optimizing performance requires detective work, and packages help to frame some basic questions about your unique packaging conditions:

• What symptoms do the packages display?

• Where do they occur?

• When do the issues happen, and when did they first occur?

• And What has changed in your packaging process?

When a client needed new sealing jaws for a flow wrapper, we asked for sample packages so we could determine the optimal jaw design for their application.

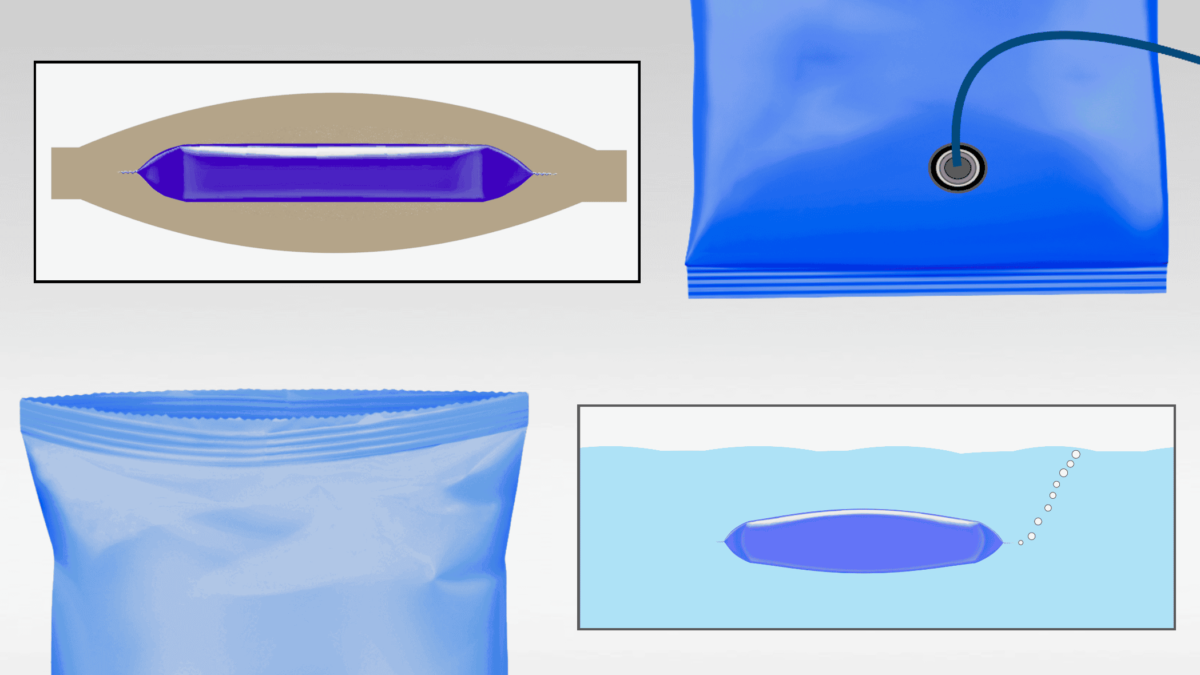

Though they didn’t report any problems, when we examined the end seals we noticed excess pressure across the fin seal fold and weak sealing pressure in other areas that could cause leakers.

The client reported that they had worked to fine-tune sealing jaw set-up and temperature settings across the whole line, which included three different wrapper models, but these issues continued to persist.

Solutions

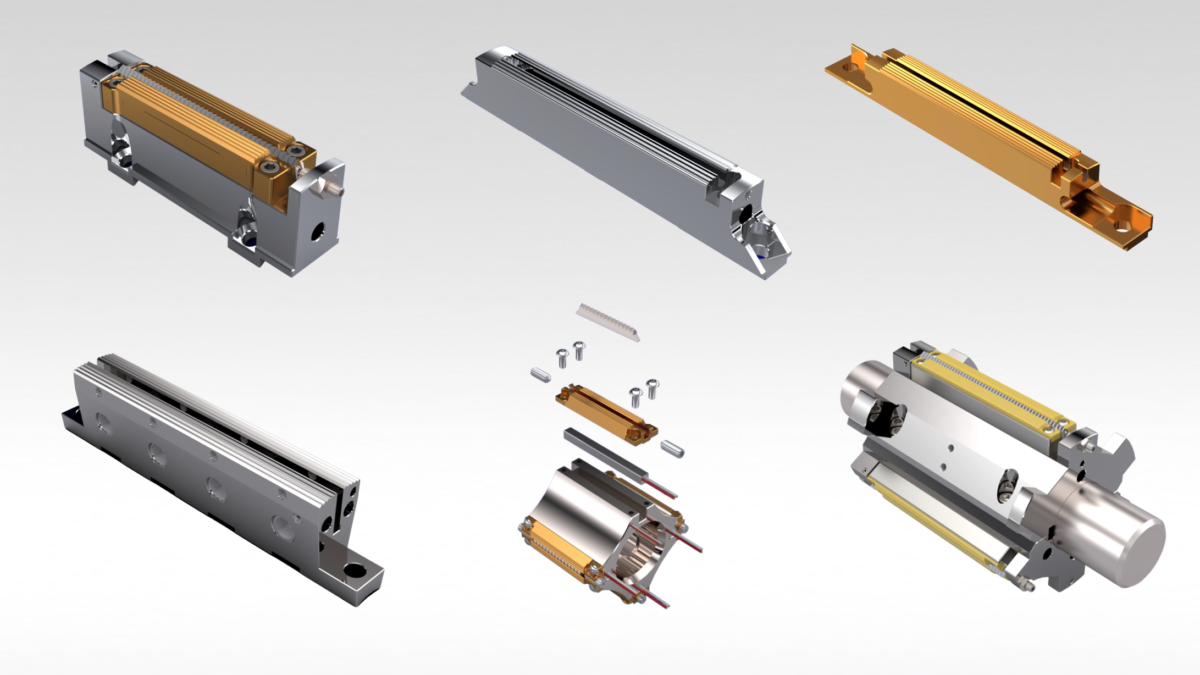

They had come to accept that marginal package appearance, along with occasional leakers at the fin seal fold, were unavoidable. But we saw no need to settle for minimally acceptable packages, and recommended our Easy Seal™ FLEX jaw design.

A trial of the Easy Seal™ jaws on one wrapper substantially improved both package appearance and seal integrity.

The FLEX jaw faces provided more uniform sealing pressure across the end seal.

We provide Easy Seal™ Jaws with a variety of different materials. In this case we utilized Dura-Therm, which conducted more consistent sealing temperatures across the jaw faces to help seal off leakers without overheating.

Our client successfully converted the entire line to Easy Seal™ FLEX jaws, and realized some additional benefits:

• The QUICK-CHANGE inserts provided faster, more precise set-ups and reduced jaw replacement costs.

• The knife and anvil design was now the same across different makes and models of wrappers, which reduced inventory costs and allowed them to standardize set-up procedures.

Do you have packaging improvements waiting to be made? Send Greener Corporation your sample packages. Our technical staff will help you optimize the performance of your whole packaging process, including Parts, Process, and People.