Are you planning to test or convert to sustainable packaging films on your flow wrappers or vertical form-fill-seal baggers? Your current machine set-up and components may not provide quality results with these paper-based, recyclable, or compostable materials.

This Greener Tech Bite outlines steps in your packaging process that you should evaluate and adjust before running these new films. You’ll find links to resources for:

• Machine Set-Up • Standard Operating Procedures

• Sealing Jaw & Former Design • Training

Compared with your current film, sustainable materials may:

• be thicker or stiffer

• be more easily damaged

• or require a different, and perhaps narrower, sealing temperature range

Their machinability and sealability differences can impact everything from film unwind and package formation through to the finished, cut and sealed package.

Package Formation

Sustainable materials may bend and fold differently and be more easily wrinkled or damaged, causing cutting and sealing problems and poor package appearance.

Follow these links to review package formation adjustments and former designs that will help accommodate these differences:

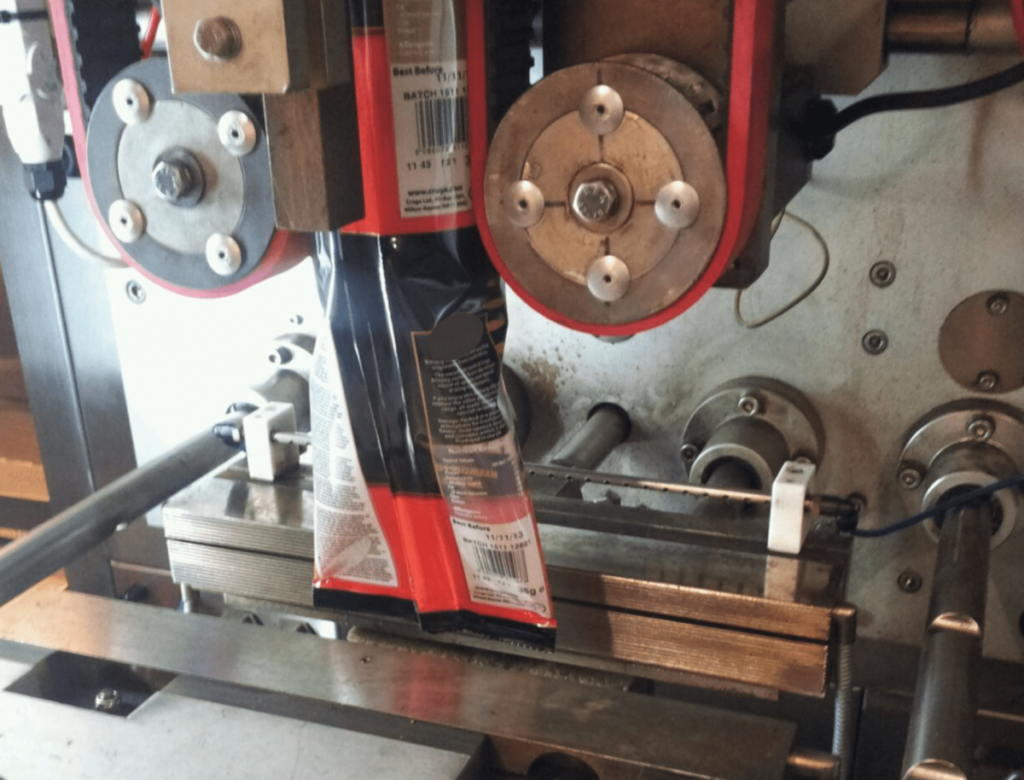

Sealing and Cutting

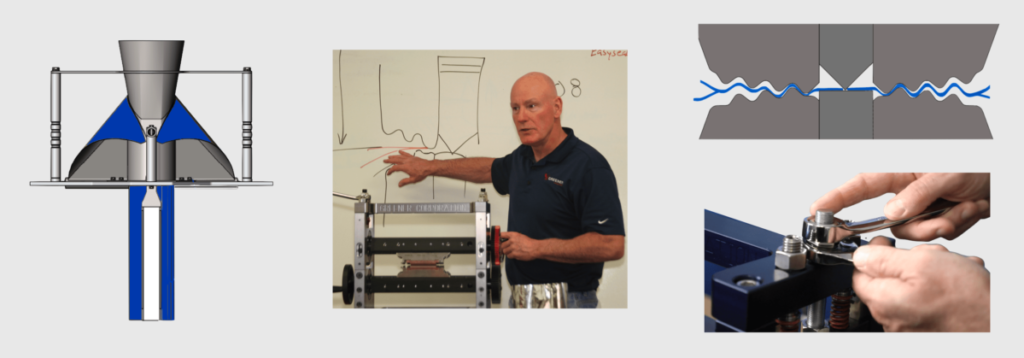

The set-up and design of your sealing jaws and knives should also be evaluated and adjusted for the new film.

For Flow Wrappers and Vertical Baggers

These resources on carbon impressions will help you identify sealing and cutting problems and develop solutions.

This Tech Bite will help you maintain more consistent sealing temperatures across the face of your jaws.

Your sealing jaws should be designed for the specific characteristics of the new, sustainable material.

Standardizing this jaw design across wrappers, lines, and facilities will help ensure consistent, quality results.

More Resources for Flow Wrappers

Working With Greener

Greener can work with you at any point on your sustainable film project, even in the early, conceptualization stages. In addition to recommending and delivering revised component designs, we can:

• Provide remote or on-site Technical Service

• Help you develop revised Standard Operating Procedures (SOPs)

• Present Training programs to implement the new SOPs

These case studies, though they do not involve sustainable films, demonstrate the full-process support that Greener can provide:

For more technical resources specific to your project variables, contact Greener Corporation. We develop and deliver full process solutions, worldwide.