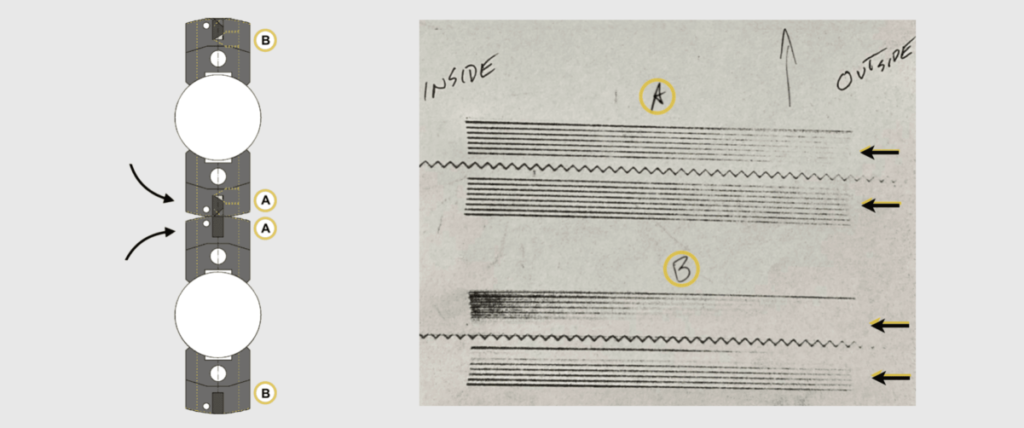

Sealing jaw carbon impressions provide a vital roadmap for diagnosing and troubleshooting problems on flow wrappers and vertical baggers. This Greener Tech Bite demonstrates how multiple issues can be revealed by a single impression.

Clearance

These carbons, labeled A and B, were made by the two-up, rotary sealing jaws on a flow wrapper. Both impressions show inadequate sealing pressure on the outer, operator end of the jaws. The head clearance needs to be readjusted so that the jaw faces are parallel.

Misalignment

Both pairs of jaws are also misaligned. The serrations only engage at narrow pressure points, displayed as distinct lines on the carbon impression.

Cutting Issues

The carbon for pair B shows two knife impressions, indicating a cutting issue that could be causing seal problems. A zig zag impression was made by the currently installed knife. The lighter straight impression was produced by a score mark in the anvil from a previously used straight knife. The anvil had not been changed when the new zig zag knife was set up.

Without a clean surface to cut against, the zig zag knife had to be over-adjusted. This likely caused the upper and lower jaws to bounce apart and leave the gap in the end seal that appears on these impressions just below the slot.

Additional Symptoms

Pair B also displays additional symptoms. The impression shows one consistent line where the jaws first came together, but then heavy sealing pressure on the inside end tapers and disappears half-way across. Another single line of contact appears just after the slot.

Multi-Step Problem Solving

Resolving the problems revealed by these carbon impressions required multiple steps that can’t be adequately detailed in this post and video. But this case is a good reminder of a basic problem-solving strategy: As you install new parts or troubleshoot problems, make only one adjustment at a time.

Then take another carbon impression and compare it with previous results. Did your adjustment improve the problems, make them worse, or create new issues? Through this systematic method you will get the clear feedback you need to refine each adjustment before taking additional steps, and you will also be improving your troubleshooting skills.

Discover more posts and videos about carbon impressions, including tips on the most accurate paper for your machinery and situation, on our Technical Resource Blog. And make carbon impressions a standard component of your installation, troubleshooting, and preventative maintenance procedures.