Most traditional flexible packaging is made from multiple layers of different materials that can’t be easily separated. Mono polyethylene (PE) and mono polypropylene (PP) are produced from the same or similar materials, and are the most common polymer-based recyclable materials we’ve encountered so far.

Segment 2 in our Sustainability Series explores the properties that can make mono PE and mono PP more challenging to form, cut, and seal, and presents solutions for maintaining package quality and machine speeds when running these materials on flow wrappers and vertical FFS baggers.

FORMING Mono PE & Mono PP Packaging Materials

During the forming process, the thicker, stiffer nature of mono PE and mono PP structures creates greater tension in the web. On both flow wrappers and vertical baggers, a power film drive will help keep these structures tracking properly.

Specially designed formers are often required to maintain consistently sized packages that are free from creasing and scoring.

CUTTING Mono PE & Mono PP Packaging Materials

The mechanical properties of these thicker and stiffer structures can also make cutting more challenging.

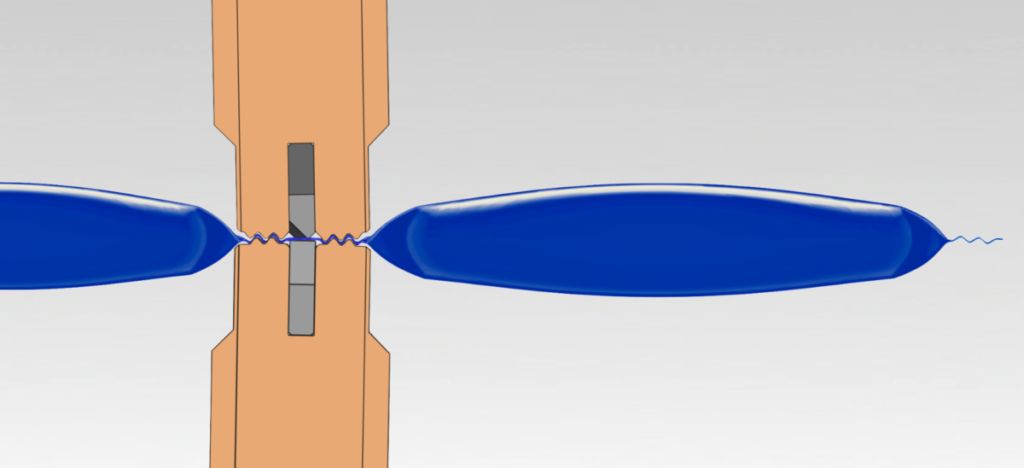

Knives designed for your specific packaging material will improve cutting performance.

Special features such as extreme angle zig zag knives can improve openability for the consumer.

SEALING Mono PE & Mono PP Packaging Materials

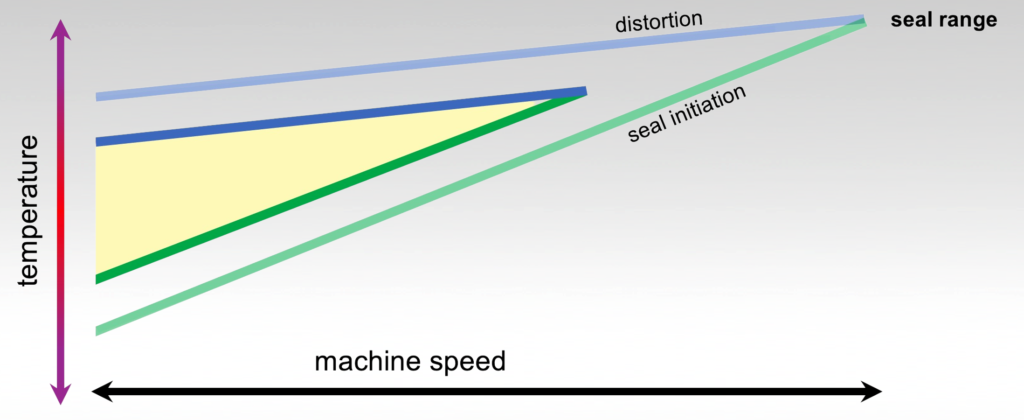

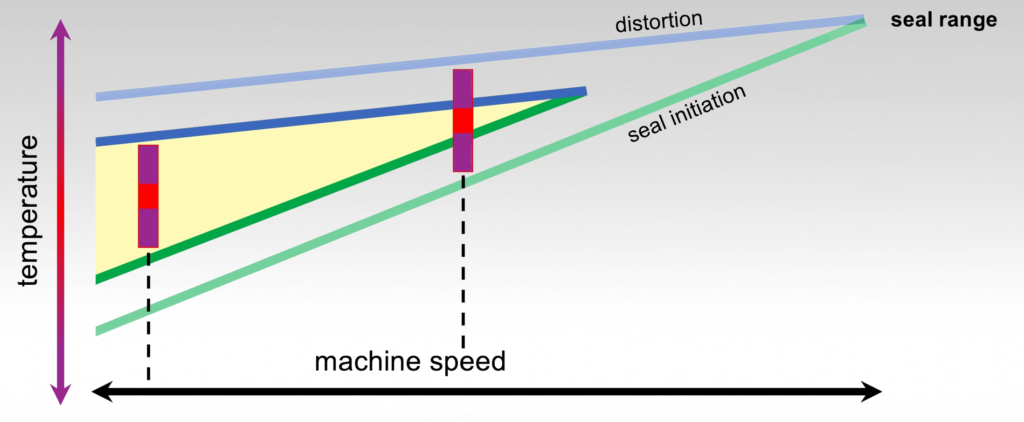

As explained in our previous Tech Bite, the effective seal range of a packaging material is defined as the difference between the seal initiation temperature and the distortion temperature.

With all flexible packaging materials, machine speeds are limited by the need to fit normal sealing jaw temperature cycles within the seal range.

Many current mono PE and mono PP structures have a lower distortion temperature, which decreases their seal range.

And since these mono structures tend to be thicker and stiffer, higher sealing jaw temperatures are needed for heat to reach and activate the sealant layer. This further reduces the seal range.

With sealing jaw temperature increases limited by the lower distortion point, reductions to machine speed may be necessary to provide adequate dwell time for seal initiation.

Sealing Solutions

Advanced sealing jaw designs can help mitigate sealing issues encountered with mono PE and mono PP materials. Sealing jaws made from Greener Corp’s proprietary Dura-Therm alloy provide more responsive and consistent thermal conductivity across the sealing face to reduce temperature cycle fluctuations and help maintain seal quality and machine speeds.

Temperatures don’t spike as high when the machine idles, or drop as far when the line restarts.

Customized sealing jaw serration patterns and options such as Easy Seal™ FLEX jaws can also reduce temperature cycles by optimizing thermal transfer and sealing pressure.

In addition to sealing jaw design, optimized adjustment procedures and training are critically important for maintaining seal quality and machine speeds on flow wrappers and vertical baggers.

To learn more about sustainable flexible packaging materials, advanced part designs, machine adjustments, and training, contact Greener Corporation.

We provide integrated parts, industrial packaging solutions and technical services worldwide.