Packaging material seal range and sealing jaw temperature cycles can limit seal quality and reduce machine speeds on flow wrappers and vertical baggers.

This Greener Tech Bite explains the factors that determine seal ranges and presents solutions for maintaining temperature cycles within this range to optimize package quality and productivity.

Packaging Material Seal Range

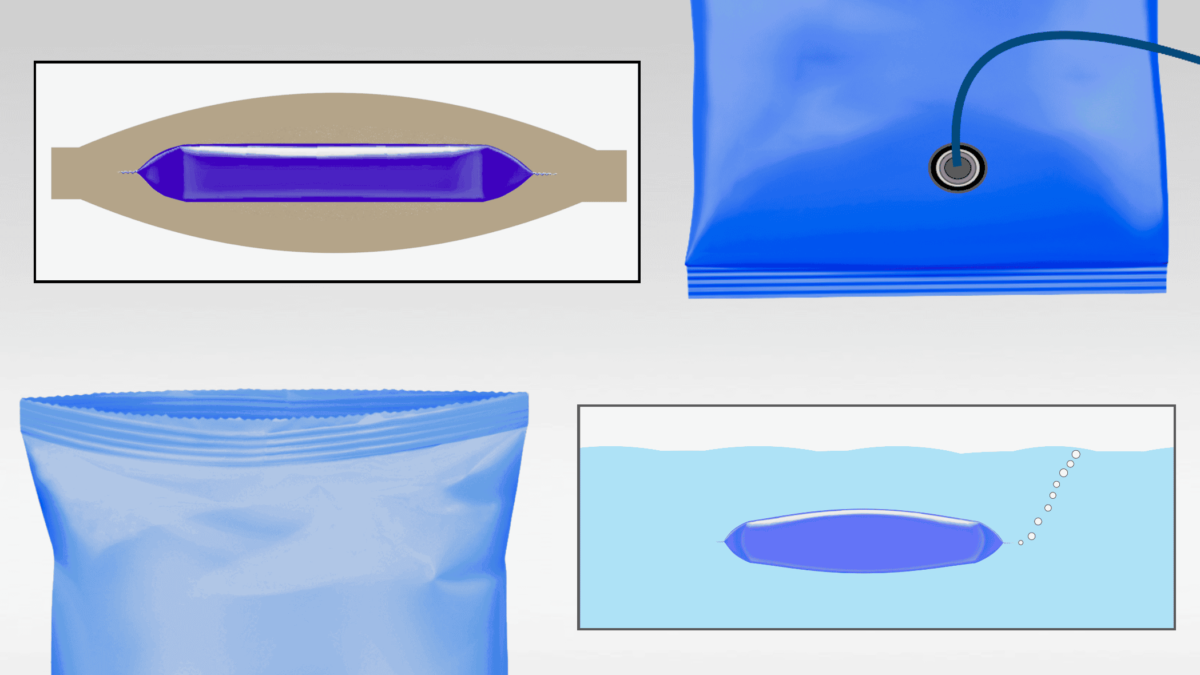

During the sealing process, temperatures are highest where the sealing jaws contact the package and then dissipate as heat travels through the core layers to the sealant. This heat transfer becomes a race against time. The goal is to reach seal initiation temperature at the sealant layer as quickly as possible without heating the core layers to their distortion temperature.

A material’s seal range is defined as the difference between the seal initiation temperature and the distortion temperature.

Sealing Jaw Temperature Cycles

Steady Production

A wide seal range allows for normal variability within the packaging process. A main source of this variability is the normal temperature cycle of the sealing jaws.

During steady production, temperatures dip as the sealing jaws transfer heat to the packaging material and then recover when the heat cartridges are energized. These fluctuations generally cycle within a few degrees on most machines.

Interrupted Production

But when production is interrupted, the sealing jaws are no longer transferring heat to the packaging material and jaw temperatures spike.

When production resumes, temperatures drop significantly and then, after a few moments, recover and return to normal.

Seal Range and Temperature Cycles

An appropriate seal range must allow for sealing jaw temperature cycles that include the impact of production interruptions.

When materials with a narrower seal range are run, or when temperatures cycle above or below the seal range, poorly sealed and distorted packages are produced.

Seal Range and Machine Speed

The effective seal range narrows as machine speed increases and seal dwell time is reduced. When heat reaching the sealant layer fails to attain seal initiation temperature, compensating temperature increases are limited by the distortion temperature of the core material layers.

Seal Range, Machine Speed, and Temperature Cycles

Maximum production speeds are limited by the seal range of the packaging material, which must accommodate the temperature cycle of the sealing jaws.

For high-speed applications, film suppliers can provide materials with lower seal initiation temperatures that increase machine speed potentials. But these materials are often more costly.

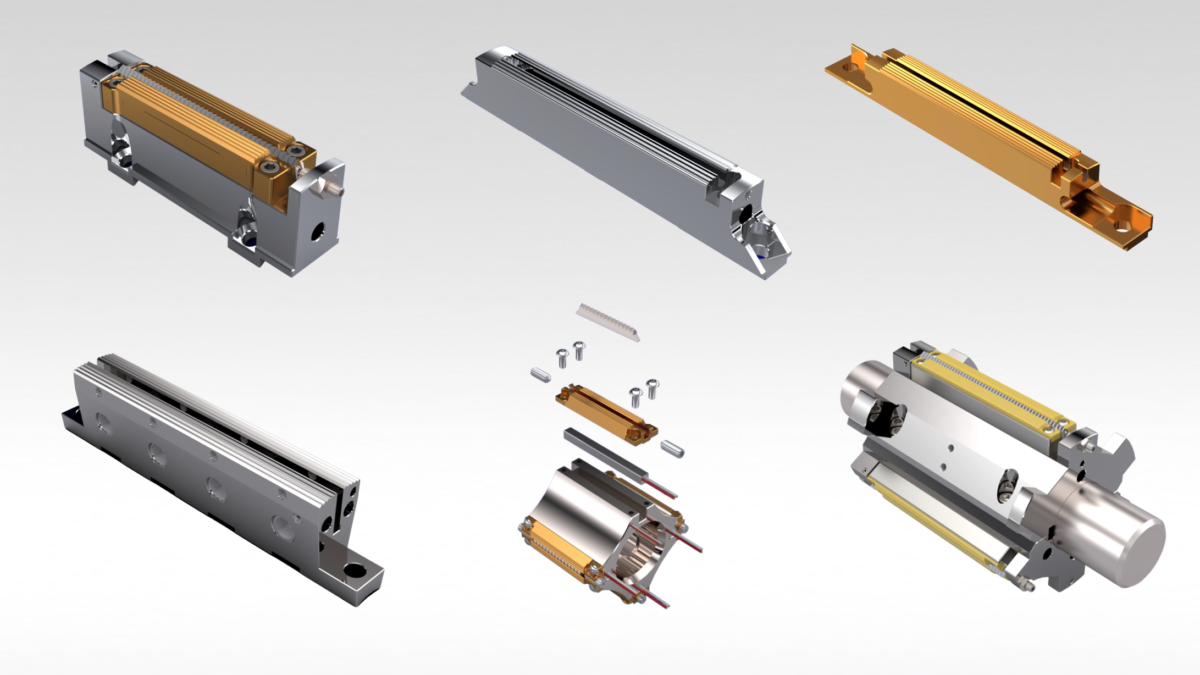

Dura-Therm Sealing Jaws

Sealing jaws made from Dura-Therm, a durable alloy with excellent thermal conductivity, have been shown to decrease temperature cycle fluctuations by 80% or more.

Dura-Therm sealing jaws provide excellent seal quality at higher speeds and for packaging materials with narrower seal ranges, such as today’s sustainable mono materials.

Specially designed sealing jaw serration patterns can further reduce temperature cycles by optimizing sealing pressure and heat transfer.

To learn how we can help you optimize seal quality and machine speeds, and to run packaging materials with narrower seal ranges, contact Greener Corporation. We provide integrated parts and technical services worldwide.