When solving packaging problems, you’ll achieve the best results when you diagnose one symptom at a time and evaluate the effects of each corrective adjustment. This systematic approach will help you isolate the causes, determine the best solutions, and avoid steps that compound the problem and waste time.

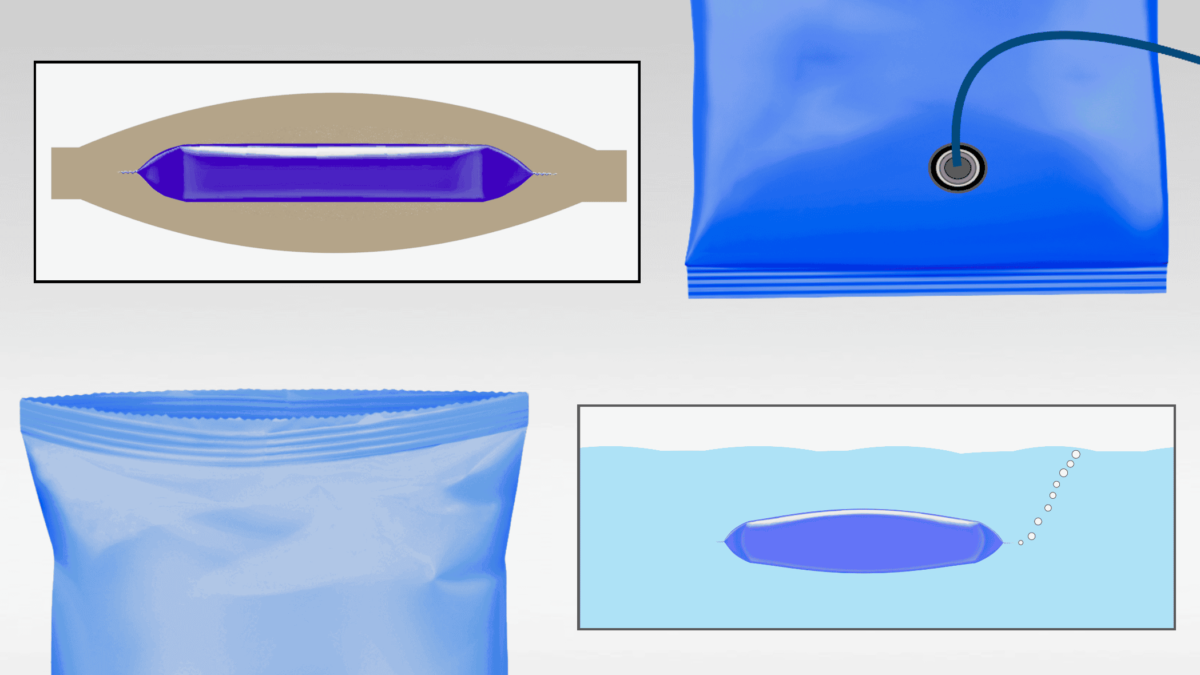

In part 1 of this Greener Tech Bite we diagnose the most apparent problem on this package from a flow pack wrapper—the split in the upper left corner.

Split, Fractured Seals

Wrinkles & Creases

The leading edges of the sealing jaws are fracturing the film at the site of a wrinkle, which has likely caused or at least contributed to the problem. Extra wrinkles and creases can be reduced or eliminated by refining the product feed and package formation process. Use these links to consult posts and videos that explain these adjustments.

Let’s assume that our adjustments improved but did not eliminate the wrinkles. The splits still occur, but they are less severe. We need a carbon impression to determine our next steps.

Clearance

The carbon indicates more pressure on the end of the sealing jaws where the splits appear. This could indicate that clearance was not properly adjusted when the jaws were set up, or that clearance has since been changed.

As a general rule, clearance should be adjusted at initial set up and not altered. But to solve our problem we need to reset clearance and check it with a new carbon impression.

Alignment

The new impression displays more consistent sealing pressure; clearance has been correctly set. If the the splits persist, our next step is to fix the moderate serration misalignment shown on the carbon.

Backlash

Check for and remove backlash between the upper and lower sealing jaws. To learn more about adjusting backlash consult these posts and videos.

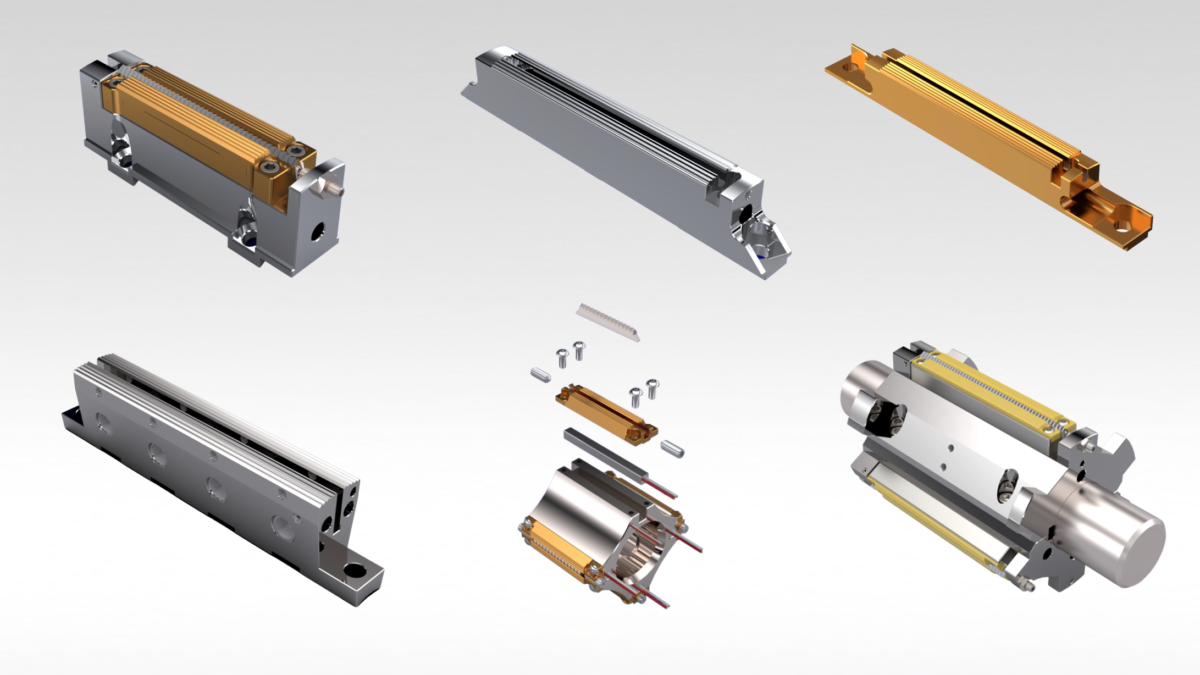

Sealing Jaw Design

If clearance and alignment adjustments don’t eliminate the split packages, an optimized sealing jaw design may be required to solve the problem.

Serration Pattern

The serration pattern should provide even, consistent sealing pressure for your specific film, package configuration, and running conditions.

Fracture Elimination Design (FRED)

You might need special design features such as Greener’s Fracture Elimination Design, which alleviates excess pressure at the leading edge of the sealing jaws that can fracture the package.

Diagnosing Packaging Problems – Part 2

Leakers & Inconsistent Pressure

Once you make the adjustments and jaw design changes necessary to eliminate splitting and fracturing, your package may still have problems with leaks and inconsistent sealing pressure. Packagers often need to maintain a narrow, difficult to achieve operating window that provides enough pressure to seal off leaks and avoids excess sealing pressure that splits or fractures the package.

We will diagnose potential causes and solutions for these problems in Part 2 of this Greener Tech Bite.