Worn gears are often overlooked as a cause of set-up and sealing problems on flow wrappers. In this Tech Bite one of Greener’s technical experts encounters these issues when rebuilding a client’s cutting and sealing head at our manufacturing facility.

Symptoms

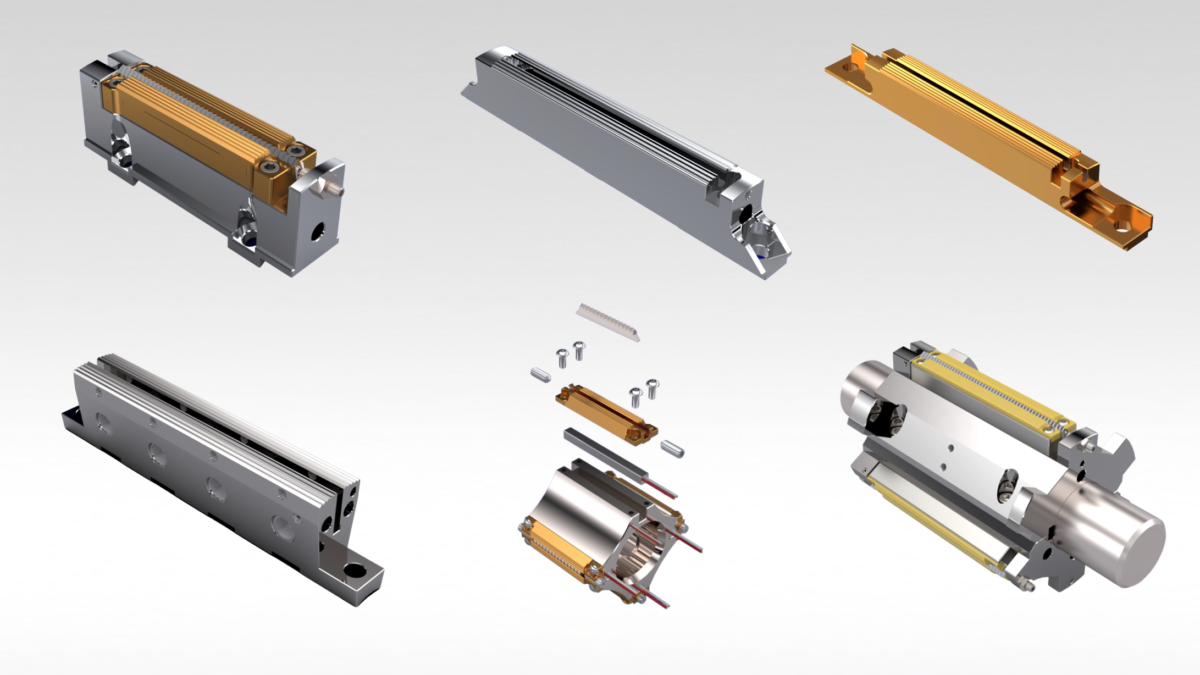

He had installed many new components on the head, including shafts, bearings, springs, and two pairs of sealing jaws. When he rotated the jaws together by hand, one pair meshed smoothly. But the second pair was too tight and took extra effort to rotate through.

Possible Causes

The old set of gears had been cleaned and reinstalled. Since only one pair of jaws was tight, he suspected that the gears were worn. But before checking them, he needed to ensure that the new components were not out of tolerance and causing the disparity.

• The shafts were consistent and true.

• If the new bearings were defective, problems would occur intermittently. But in this case the issue was consistent.

• Both pairs of sealing jaws were new and proved to be the same design and height.

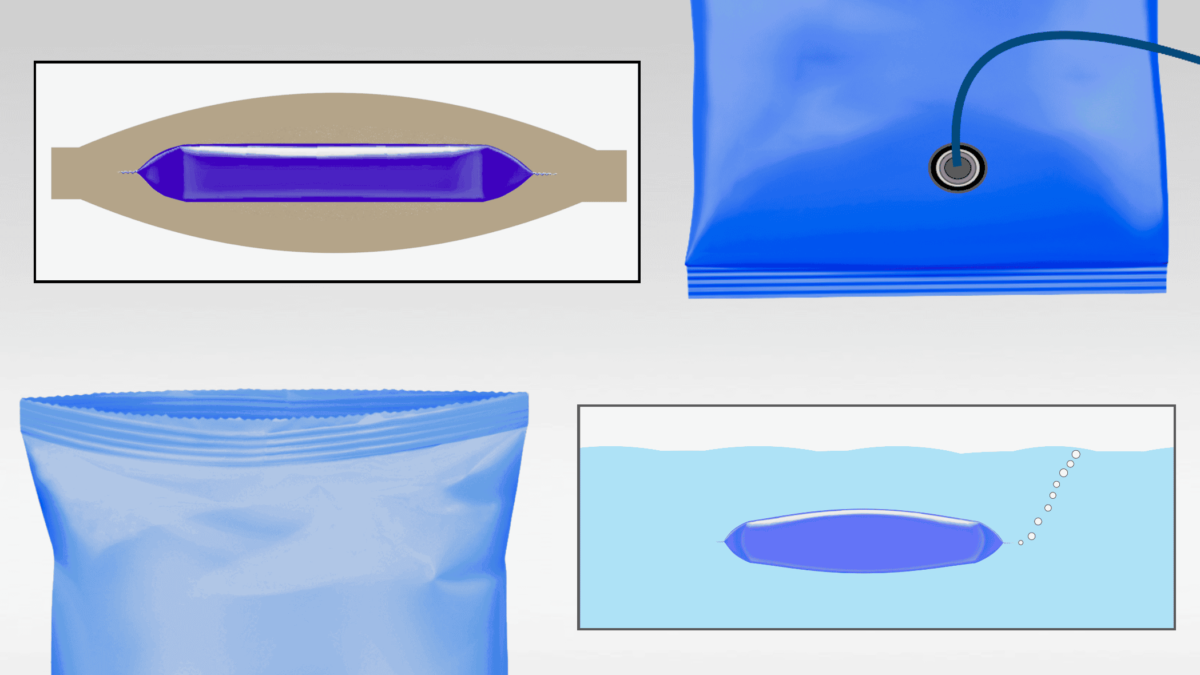

Had he been troubleshooting a wrapper on a client’s packaging floor, he would make sure that a matched set of jaws had been installed. Mixing together new and used jaws or jaws with different serration patterns can create problems.

Uneven Gear Wear

More gear wear typically occurs on the teeth that engage as the sealing jaws come together.

This wear creates extra space between these gear teeth.

On the rebuilt head the gear wear corresponding to one pair of jaws was much greater than for the other pair. The split gear had been over-adjusted to remove the extra spaces between the most worn teeth. This made the rest of the gear teeth mesh too tightly and as they rotated through.

Solutions

The problem resolved when worn gears were replaced with a new set. Both pairs of jaws aligned properly and meshed together smoothly, without any binding.

When you are troubleshooting problems or doing periodic maintenance on flow wrappers, be sure to inspect the gears for excessive wear. And for additional technical resources, consult our wide range of additional posts and videos and contact Greener Corporation.

We develop and deliver full process solutions, worldwide.