In Part 1 of this Greener Tech Bite we diagnosed potential causes and solutions for the the splitting and fracturing in the upper left corner of this package.

Here in Part 2 we’ll diagnose problems with uneven pressure and leakers that can persist after adjustments and sealing jaw design changes have eliminated the splitting.

Inconsistent Pressure & Leaks

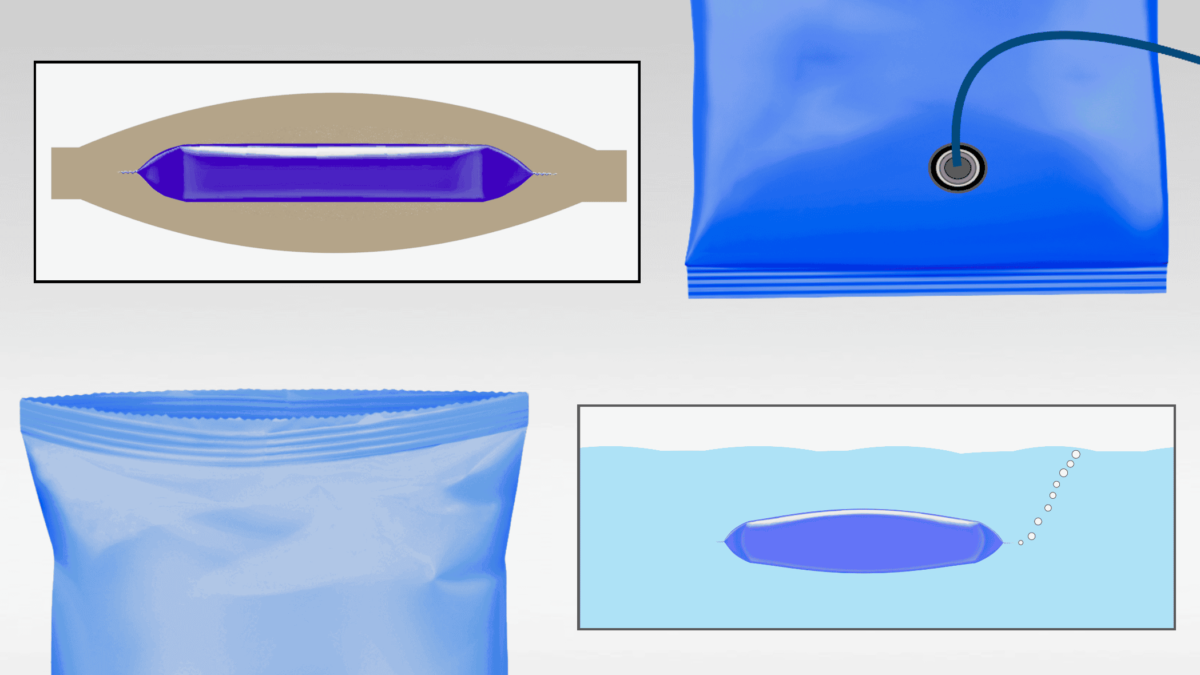

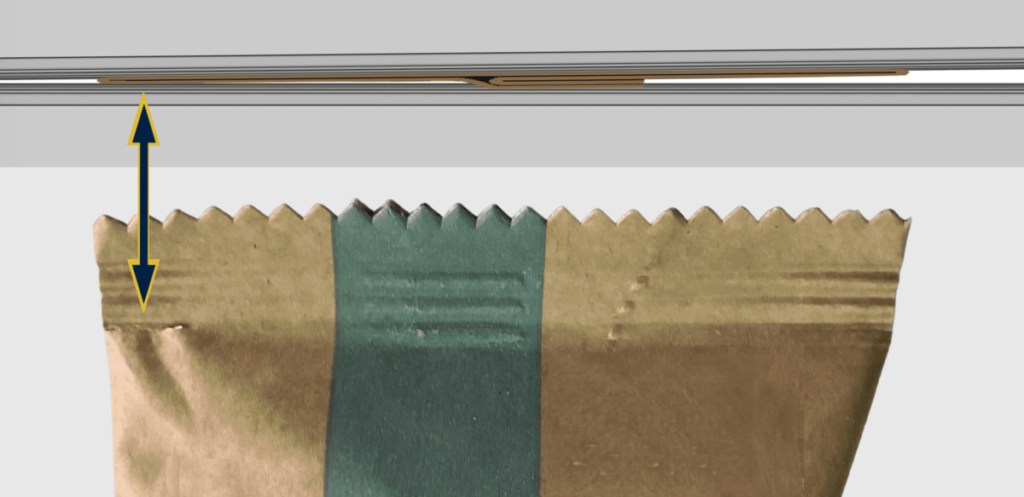

The basic design of a flow wrapper package can make it difficult to maintain consistent pressure across the seal. The double thickness of film of the fin seal can act as a bridge and keep the sealing jaws from applying adequate pressure. Leakers often develop where the package transitions from two to four layers and at the corners.

Balancing Pressure

Adjustments made to seal off these leaks often create excess pressure points and could easily bring back the splitting problem we resolved in Part 1. Providing the consistent pressure needed to seal off leaks without damaging the package can be difficult to achieve.

We’ve worked with clients that found it especially challenging to maintain this balance when trialing or transitioning to mono or paper-based packaging materials, which can be more sensitive.

Adjustments & Sealing Jaw Designs

Optimizing machine adjustments and sealing jaw designs will widen your operating window, so you can consistently provide the pressure to seal off leakers without damaging the package.

Here are three recommendations:

1. Heat, Time, & Pressure

First, make sure you understand the function of and relationships between heat, time, and pressure, so that you can make more informed, more effective adjustments on your packaging machinery. You can review these relationships on our previous post, Adjusting Heat, Time, and Pressure.

2. Product Feed & Package Formation

Also review the recommendations for wrinkles, clearance, and alignment in Part 1 of this Tech Bite. Even if you’re not experiencing splitting and fracturing, refinements to the product feed and package formation process will create more consistent packages with better seal integrity.

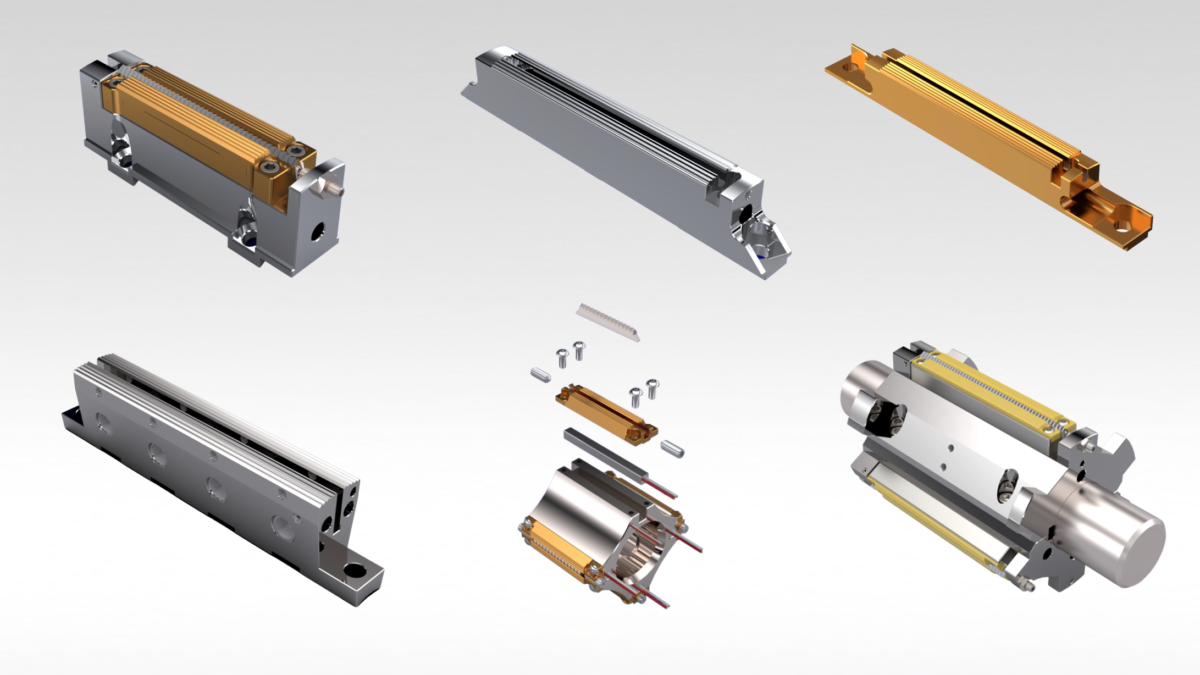

3. Easy Seal™ FLEX

In Part 1 we explained the importance of sealing jaw design for providing consistent sealing pressure. Another design option is Easy Seal™ FLEX jaws, which adapt to the extra thickness of the fin seal fold to seal off leakers and reduce excess pressure points that can damage and split the package.

Easy Seal also provides additional benefits that improve seal quality.

On heat seal applications, Dura-Therm inserts provide more consistent heat transfer to seal off leakers across the sealing face without damaging the package.

And Easy Seal QUICK-CHANGE inserts provide faster, more accurate sealing jaw changeovers.

Diagnosing Packaging Problems

Parts 1 and 2 of this Tech Bite demonstrate the need for an integrated approach to diagnosing and solving problems, one that optimizes part designs, adjustment procedures, and training for the whole packaging process.

If you’d like help developing solutions that improve package quality and productivity, contact Greener Corporation. We provide integrated parts and technical services worldwide.