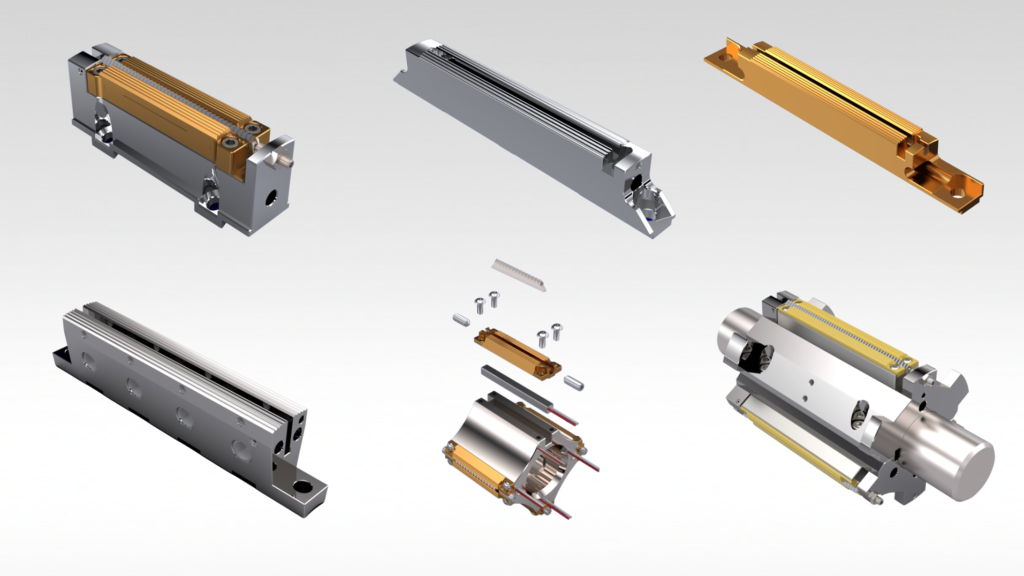

Sealing Jaws Optimize Package Quality & Productivity on Flow Wrappers

https://www.youtube.com/watch?v=t3UqRSZ3pzs?rel=0 Sealing jaws on flow wrappers are not standard, universal components; they should be designed according to the unique features of your packaging operation. When you work with Greener Corporation, we integrate your machinery design and condition, packaging materials, seal integrity requirements, and other circumstances to design and manufacture sealing jaws that optimize package quality […]

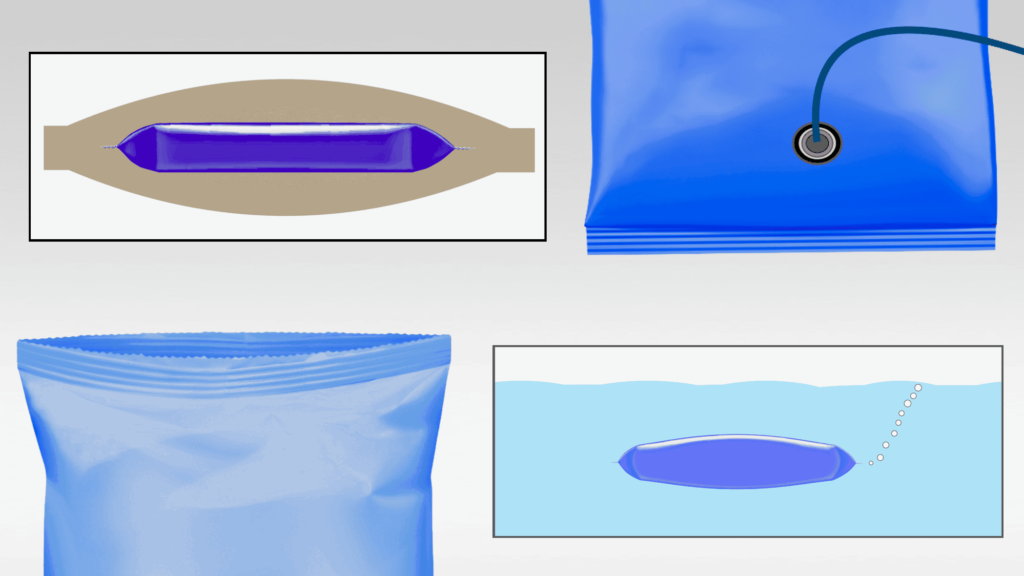

Review of Seven Seal Testing Methods for Flexible Packaging

https://www.youtube.com/watch?v=HFvXskEq54g?rel=0 Before you can determine the best seal test for your flexible packaging products, you need to clearly identify your requirements for seal strength and hermiticity. Then you can use these criteria to evaluate different methods and to accurately interpret test results. This Greener Tech Bite explains the objectives, methods, results, and limitations of seven […]

Sealing Leaks at the Triangle of Death on Flow Wrappers and Vertical Baggers

https://www.youtube.com/watch?v=mIjfge-4R_U?rel=0 Are you consistently meeting your standards for package seal integrity and production speeds on your flow wrappers and vertical baggers? This Greener Tech Bite explains causes and solutions for a common package sealing problem where high integrity seals are required—the unsealed gap where the lap seal or fin seal intersects the end seal, sometimes […]

Setting Up Sealing Jaws on Horizontal Flow Wrappers

https://www.youtube.com/watch?v=vElug6PzkXU?rel=0 Proper sealing jaw setup is critical for producing consistent quality packages; even slight misadjustments can damage the package and cause leaks that prevent you from meeting seal quality standards. This Greener Tech Bite explains nine essential procedures for accurately setting up sealing jaws on horizontal flow wrappers. 1. Clean the Shafts Begin by removing […]

Sustainable Packaging Materials 2: Running Mono Polyethylene & Mono Polypropylene on Flow Wrappers & Vertical FFS Baggers

https://www.youtube.com/watch?v=7WkI39MzRY0?rel=0 Most traditional flexible packaging is made from multiple layers of different materials that can’t be easily separated. Mono polyethylene (PE) and mono polypropylene (PP) are produced from the same or similar materials, and are the most common polymer-based recyclable materials we’ve encountered so far. Segment 2 in our Sustainability Series explores the properties that […]

Packaging Material Seal Range & Temperature Cycles on Flow Wrappers & Vertical FFS Baggers

https://www.youtube.com/watch?v=YQlSo9LR_2k?rel=0 Packaging material seal range and sealing jaw temperature cycles can limit seal quality and reduce machine speeds on flow wrappers and vertical baggers. This Greener Tech Bite explains the factors that determine seal ranges and presents solutions for maintaining temperature cycles within this range to optimize package quality and productivity. Packaging Material Seal Range […]

Sustainable Packaging Materials: 1. Types and Considerations for Flow Wrappers & Vertical FFS Baggers

https://www.youtube.com/watch?v=xPpf__A5y6k?rel=0 Introducing Greener Corporation’s NEW Tech Bites series about running sustainable packaging material on flow wrappers and vertical FFS baggers. In this first segment we introduce the basic types of sustainable materials and some fundamental considerations for selecting, testing, and running these structures. Traditional Flexible Packaging Materials Most traditional flexible packaging is made from multiple […]

Carbon Impressions Diagnose Misadjustments on Flow Wrappers

https://www.youtube.com/watch?v=1d_vdvBt090?rel=0 Carbon impressions are a vital diagnostic tool for setting up sealing jaws on flow wrappers. This Greener Tech Bite reviews nine carbon impressions that illustrate some common misadjustments. With an accurate setup, your carbon impression will be uniform and consistent over the peaks and valleys of each serration, across the length of the sealing […]

Setting Up Shim Style Knives and Anvils on Flow Wrappers

https://www.youtube.com/watch?v=ceBtli-dEq8?rel=0 Establishing accurate knife and anvil adjustment methods on flow wrappers is critical not just for cutting, but also for producing quality seals and avoiding preventable production delays. This Greener Corporation Tech Bite details setup procedures for shim style knives and anvils that consistently optimize package quality and productivity. 1. Check the Seal Before installing knives […]

Improving Hot Tack & Seal Quality on Vertical Baggers

https://www.youtube.com/watch?v=kA2tGT4oA8A?rel=0 What’s the ultimate combination of heat, dwell time, and pressure for producing quality seals on vertical baggers? The answer varies, depending on your machinery, packaging materials, and conditions. But in all cases Hot Tack is an important, but often overlooked, consideration. This Greener Corporation Tech Bite explains Hot Tack and its role in the […]