Proper sealing jaw setup is critical for producing consistent quality packages; even slight misadjustments can damage the package and cause leaks that prevent you from meeting seal quality standards.

This Greener Tech Bite explains nine essential procedures for accurately setting up sealing jaws on horizontal flow wrappers.

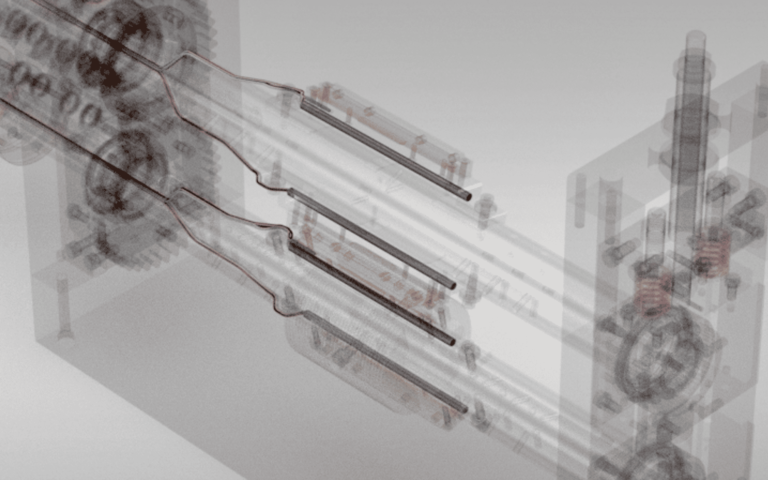

1. Clean the Shafts

2. Sealing Jaws

Replace all sealing jaws on a wrapper at the same time, and make sure all the jaws come from the same packaging machinery supplier.

You may be tempted to replace only one seal jaw, or just one of multiple pairs, to save time or reduce costs. But running sealing jaws with different wear levels or different designs causes inaccurate setups that create sealing problems.

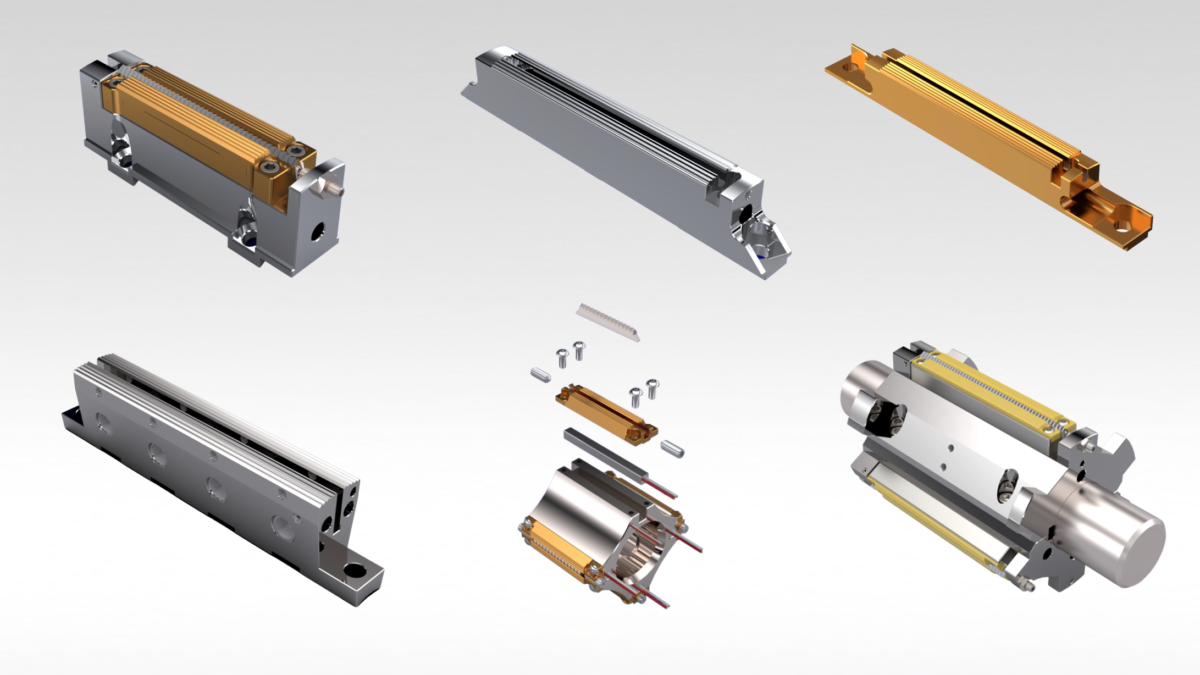

3. Insert Heaters and Thermocouples

4. Install Sealing Jaws on Shafts

Install sealing jaws with new mounting bolts and washers. Wear and damage to used bolts and washers, which can easily go unnoticed, can cause inaccurate mounting and make sealing jaws difficult to remove in the future.

5. Heat the Sealing Jaws

6. Adjust Clearance

7. Adjust Serration Alignment

Our previous post on carbon impressions diagnoses examples of misadjusted clearance, alignment, and other issues.

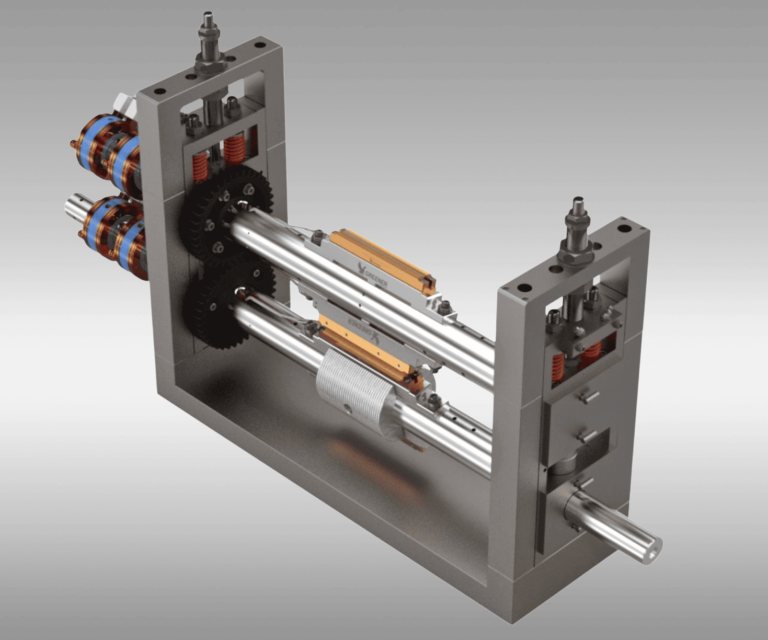

8. Remove Backlash

Next check for backlash, or independent movement between the upper and lower sealing jaws.

With even minor backlash, the resulting misaligned serrations can damage and split the package and reduce seal quality.

On gear-driven wrappers a split gear on the non-drive shaft is used to remove backlash. Belt and chain-driven machines utilize a tensioner. Over time, worn gears and stretched belts and chains contribute to backlash, so periodically inspect these components and replace them when needed.

Learn more about backlash from these Tech Bite posts and videos.

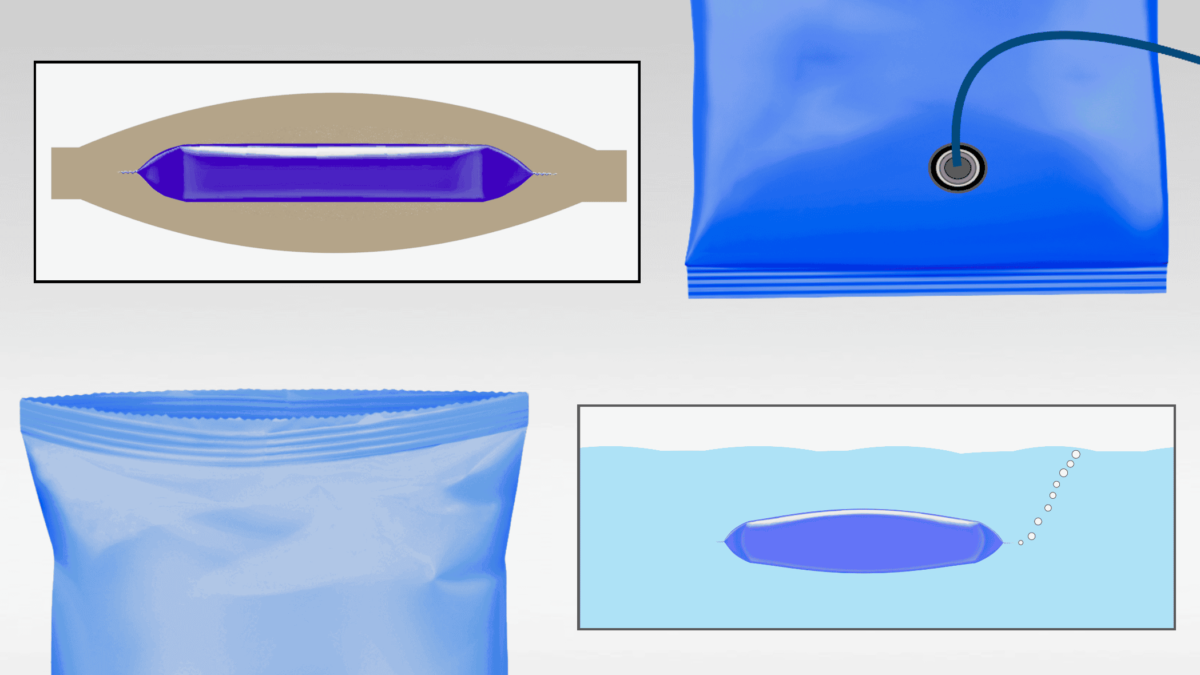

9. Adjust Sealing Pressure

The next step is to adjust spring pressure. On most wrappers springs are adjusted and locked to create the pressure required to seal and cut packages. Some wrappers utilize compression washers.

Springs and compression washers often go unrecognized as the source of package sealing problems. Since evaluating their condition can be difficult, it is well worth replacing them on a regular basis.

Adjust spring pressure as needed to meet your seal quality standards.

If you’re not producing quality seal jaws after following these procedures, discover the problem-solving solutions on our Technical Resource Blog and contact Greener Corporation for technical support. We provide integrated parts and technical services worldwide.