Line Evaluation

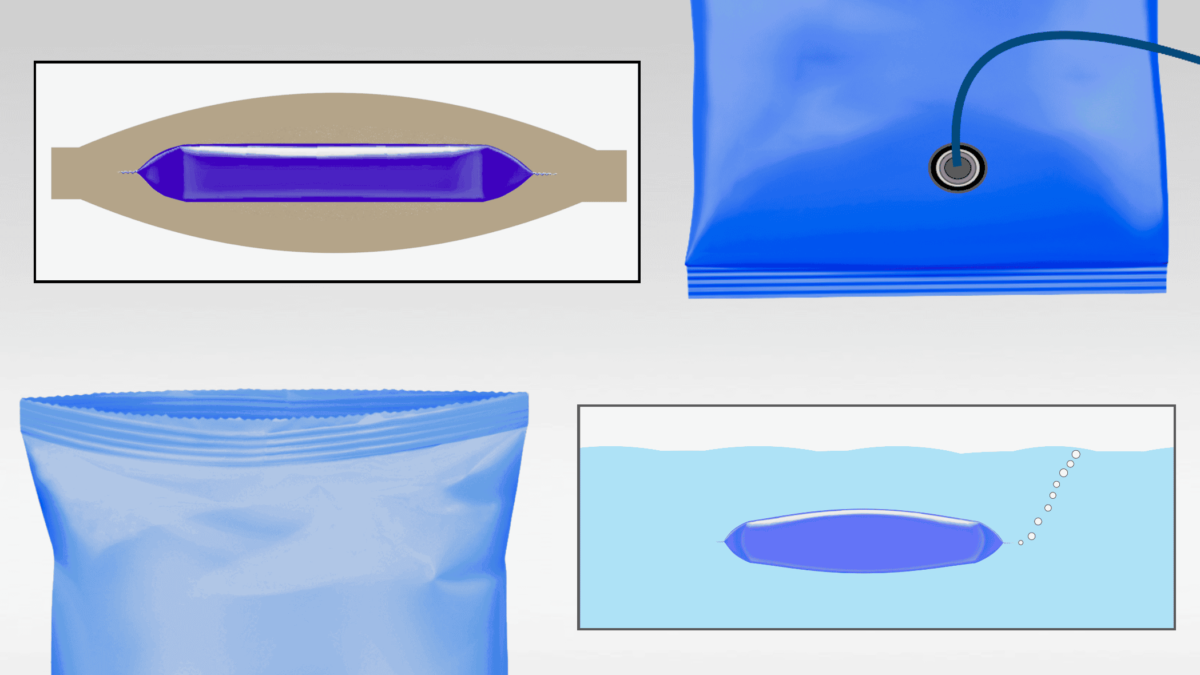

New Packaging Material: Leaking Seals

A co-packer had problems with leakers when a new film was introduced for a line of snack bars they packaged. Their scrap rate far exceeded the prescribed limit.

They brought in Greener Corporation for a line evaluation to help troubleshoot the issue and find a solution.

Our Tech Rep found that the new material had strong memory and seemed more resistant to folding than the old film. The seals were springing apart and leaking at the corners and at the fin seal fold.

But the same new material was running successfully at two other facilities; only the co-packer had leaker issues.

Unsuccessful Adjustments

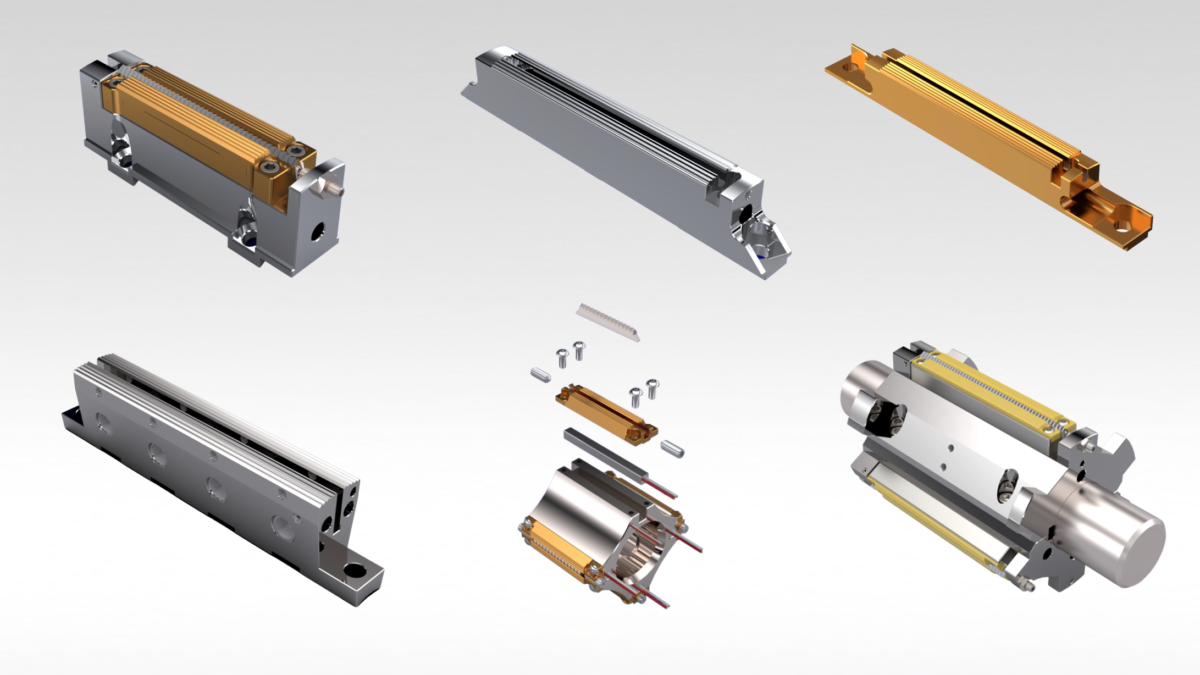

Sealing Jaws: Condition & Set-Up

Isolating the Leaker Problem

Inadequate Spring Pressure

He knew from experience that these four machines were a different make and model, with lighter duty springs, than the other wrappers at the co-packer and at the two facilities successfully running the new material.

He knew from experience that these four machines were a different make and model, with lighter duty springs, than the other wrappers at the co-packer and at the two facilities successfully running the new material.

The springs on the four problem wrappers might also be worn, since they had never been replaced.

Inadequate spring pressure would explain why previous adjustments had failed to solve the seal problems. He concluded that this new film structure required more spring pressure than the old material to force the layers together and seal off channel leaks.

Solutions

New, Heavy-Duty Springs

Greener’s Tech Rep. recommended that they order heavy-duty springs for the four wrappers, and he returned to install them. The new springs provided the additional pressure needed to produce quality seals with the new film, and the scrap rate dropped well below the allowable limit.

The packaging material change was fully implemented across all three production locations, resulting in significant cost savings.

Routine Maintenance

Evaluating the strength and condition of springs, or of compression washers on wrappers that utilize them, can be difficult.

One solution is to schedule preventive maintenance and replace springs every 1-2 years, depending on running conditions. Compression washers should be changed more often, since they can degrade more quickly and are less visible for inspection.

At the least you should understand the importance of sealing pressure and replace springs or compression washers if you suspect they are causing problems.

If you’d like help solving your packaging problems on flow pack wrappers or vertical baggers, contact Greener Corporation. We provide integrated parts and technical services worldwide.