This Greener Tech Bite, with the help of our partner Kenray Forming, explores six key design and set-up principles to help you identify the source of forming and sealing problems and develop solutions for quality packages.

1. Product Flow

Let’s start at the beginning. Problems occur most often when the product is:

• large in relation to bag size

• inconsistent in size or shape

• lightweight

• oddly shaped

• or with rough outer surfaces

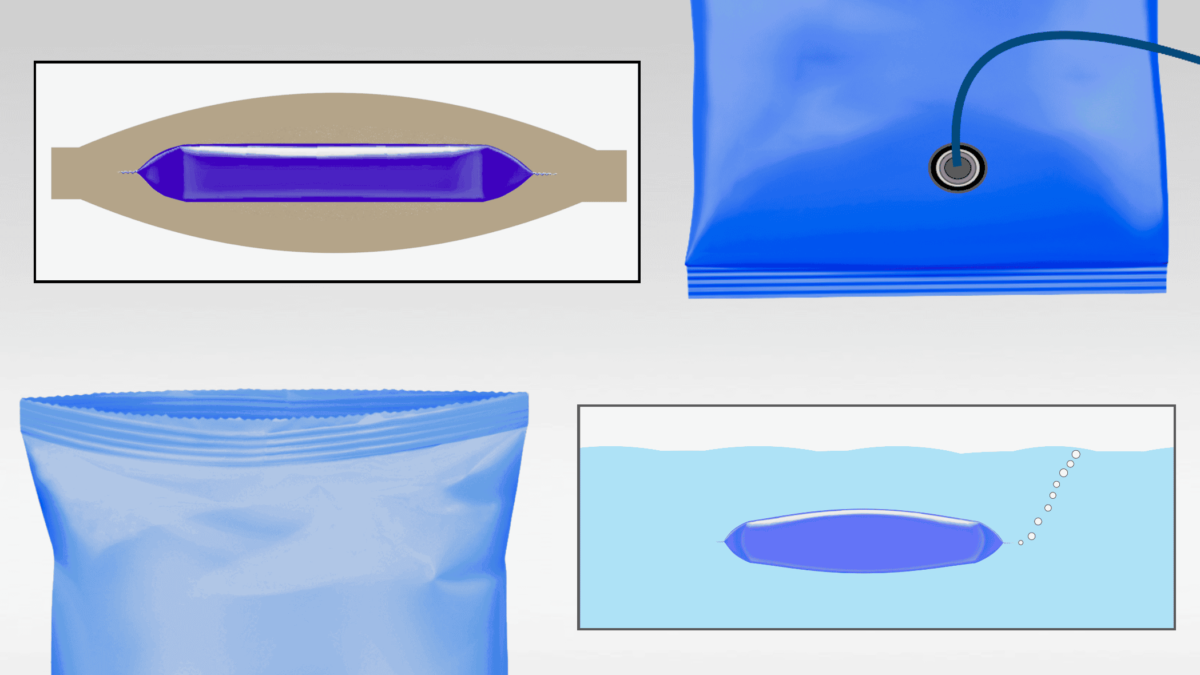

Bottlenecks occur when product strings out as it moves from the inlet chute into the narrower confines of the forming tube. In extreme cases individual product “charges” can bridge together. These product flow issues slow down production speeds, create blockages, and cause leakers when product gets trapped in the seal.

On forming tubes with integral cones the product dose is slightly staggered, so it passes through the bottleneck faster and stays more compact.

2. Forming Set Design

Forming sets should be designed according to your product, package design, machinery, and film specifications. Make sure that this optimal design is accurately and consistently replicated when you order replacement parts or specify formers for multiple machines, lines, or locations.

3. Roller Position

Machine adjustments are also critical for producing quality packages. Misaligned film rollers prevent the film from making full contact with the forming collar, causing wrinkles, creases, and package distortions that reduce shelf appeal and cause seal problems.

4. Film Drive

Poor package quality is caused by film drive issues such as belt adjustment and forming tube alignment.

5. Former Wear and Damage

Wear or damage to the former lip or wing can also distort the package.

6. Sealing

By fine-tuning your forming and filling operations you will improve both package appearance and seal quality.

Leakers

The end seals on packages produced by vertical baggers typically vary in thickness. Most have a lap or a fin seal, and some are designed with gussets. Unintended wrinkles or pleats may, at times, be unavoidable. Leakers, when they occur, often follow channels at the intersections between two and multiple layers of film and at the corners.

Sealing Jaws

Sealing jaws must transfer enough pressure and heat to seal across these channels without crushing, cutting, or distorting the end seal.

• Pressure

In order to create uniform sealing pressure, the serration profile of your sealing jaws should be designed according to your package specifications, machinery, and running conditions.

• Heat

Sealing jaw temperatures are often increased to improve seal quality, but this can create hot spots that overheat and distort the package.

Jaws manufactured from Dura-Therm material provide more responsive, consistent heat transfer across the package to help seal off channel leakers without overheating the film.

• Wear and Damage

Jaws that are worn, damaged, or contaminated with product also create inconsistent pressure and heat transfer that cause seal problems.

To learn more about forming and filling on vertical baggers, contact our partner, Kenray Forming. They provide remote training and consultancy to help you optimize your packaging operations.

For more details on sealing consult the wide variety of posts and videos posted here on our Technical Resource Blog, or contact Greener Corporation. We develop and deliver solutions worldwide.