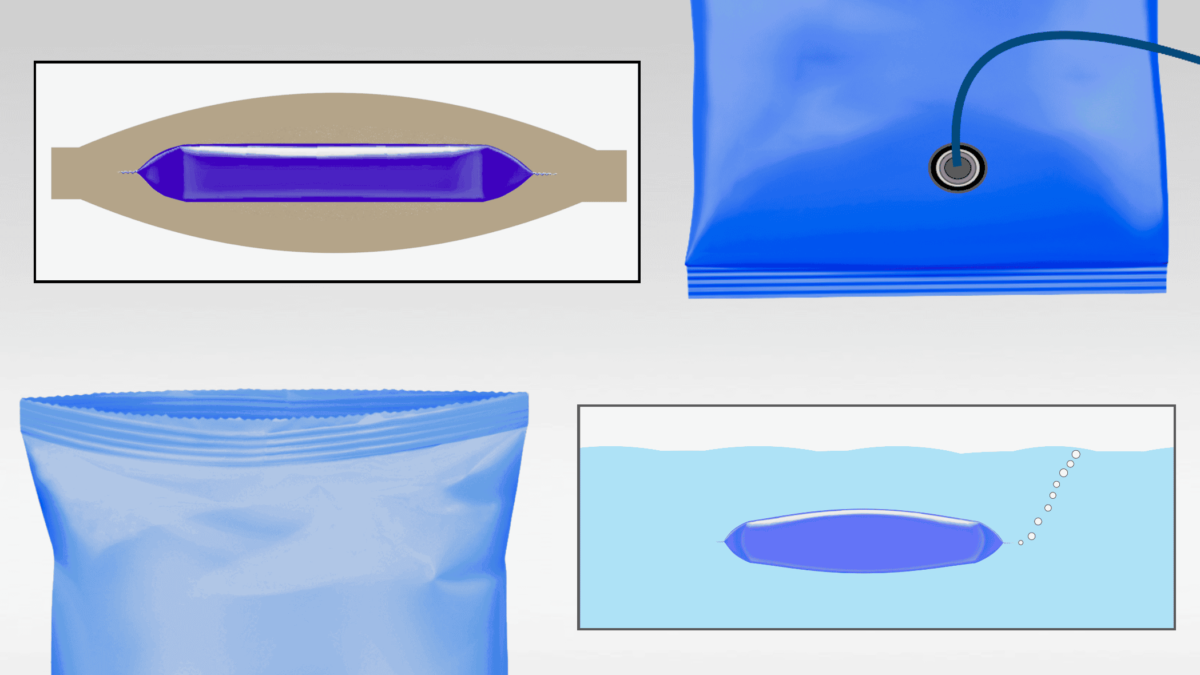

Fin wheels on flow wrappers are often overlooked as the cause of poor package quality or reduced productivity. This Greener Tech Bite explains the problems caused by contaminated and worn fin wheels and reviews maintenance and design options that will help you prevent these issues.

Most wrappers utilize at least two, and often three, pairs of fin wheels.

The first pair, typically unheated, works primarily to draw the film tube forward through the wrapper.

The second and third pairs seal the fin and guide the film tube forward.

Fin Wheel Problems

Slippage

As fin wheels wear or grow contaminated with product, ink, or film residue they begin to slip against the film. This slippage distorts the fin seal with wrinkles and creases that channel leaks in the end seal and make the package unappealing to consumers.

Pressure

Increasing pressure between the fin seals may help get you through a production run, but they should be cleaned or replaced, if worn or damaged, as soon as possible.

Relying on excess pressure will further degrade the condition of the fin wheels and wear out the shafts and bearings.

Heat

Raising the temperature setting to compensate for poor seal quality can damage the film and further contaminate the fin wheels with film residue or product.

Fin Wheel Maintenance

Fin wheels should be regularly cleaned and inspected as part of your preventative maintenance program. Replace them when they begin to wear.

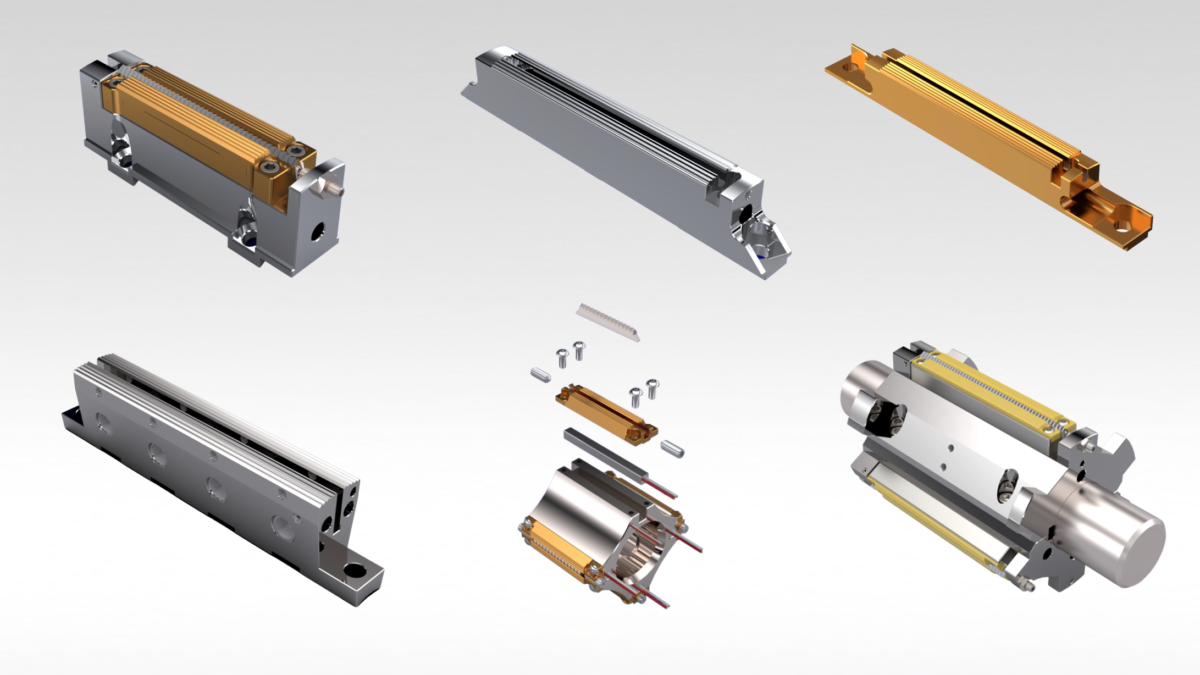

Fin Wheel Design

When you need new fin wheels, Greener will recommend the optimal design for your packaging film, product, and running conditions. Design options include serration profile, material, and seal width.

Serrations

We recommend gripper grooves on the first pair of fin wheels. This design draws the film with less pressure and helps prevent slippage.

Material

High Durability Stainless fin wheels provide excellent durability and prevent rust and corrosion without the need for plating.

Dura Therm provides consistent, responsive heat transfer to help maintain narrow temperature windows. This material also offers excellent corrosion resistance.

Seal Width

Opportunities may exist to reduce the fin seal width on your package and decrease film costs.

Standardization

Our Project Development team can help you standardize fin wheel designs across multiple makes, models, and lines of flow wrappers to achieve consistent performance.

Optimizing the design of your fin wheels and regularly inspecting, cleaning, and maintaining them will help you achieve peak package quality and productivity on your flow wrappers.