Damaged or poorly performing sealing jaws on flow wrappers can cost you hours of lost production time. Greener Corporation’s Easy Seal™️ QUICK-CHANGE Jaws decrease changeover times from hours to minutes, and at the same time improve seal quality, reduce part replacement costs, and create opportunities for standardization.

Decrease Downtime

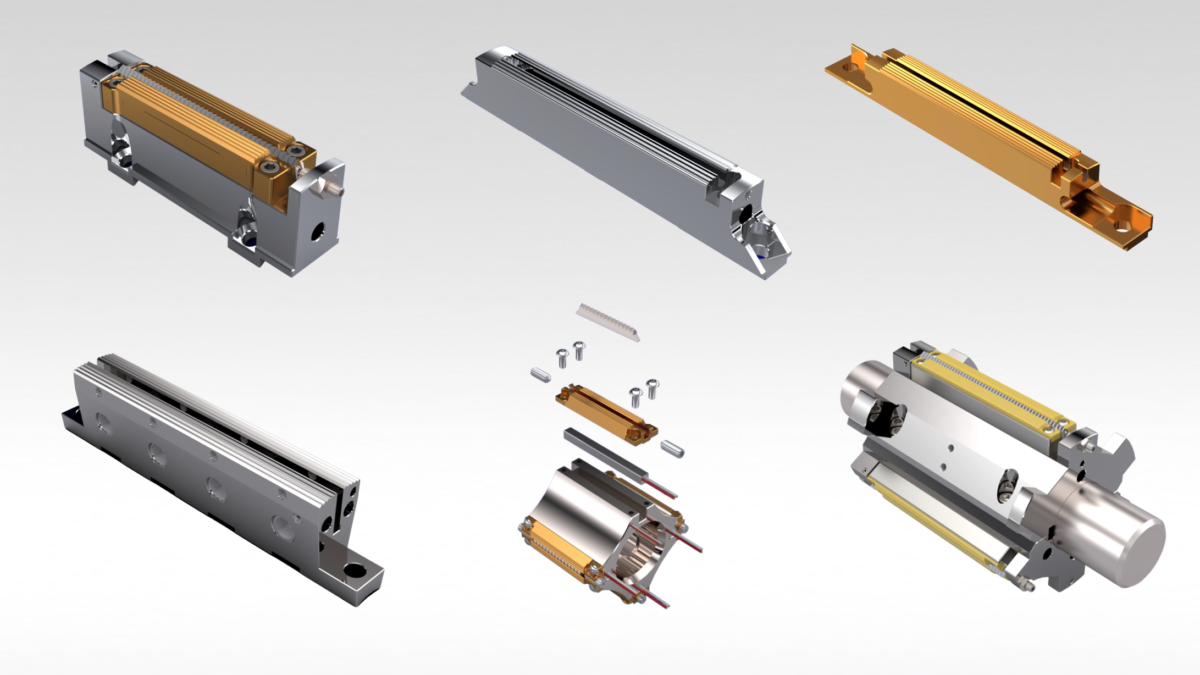

The initial Easy Seal™ installation includes bases, QUICK-CHANGE inserts, knives, and anvils.

When jaws are replaced the heaters and thermocouples, if utilized, stay in the bases, which remain accurately positioned on the shafts. New Easy™️ Seal QUICK-CHANGE inserts fit precisely into the bases, so the serrations are already aligned. Making the packaging equipment installation quick and consistently accurate.

New knives and anvils can then be adjusted to cut, and you can be back up and running in less than an hour total.

Improve Seal Quality

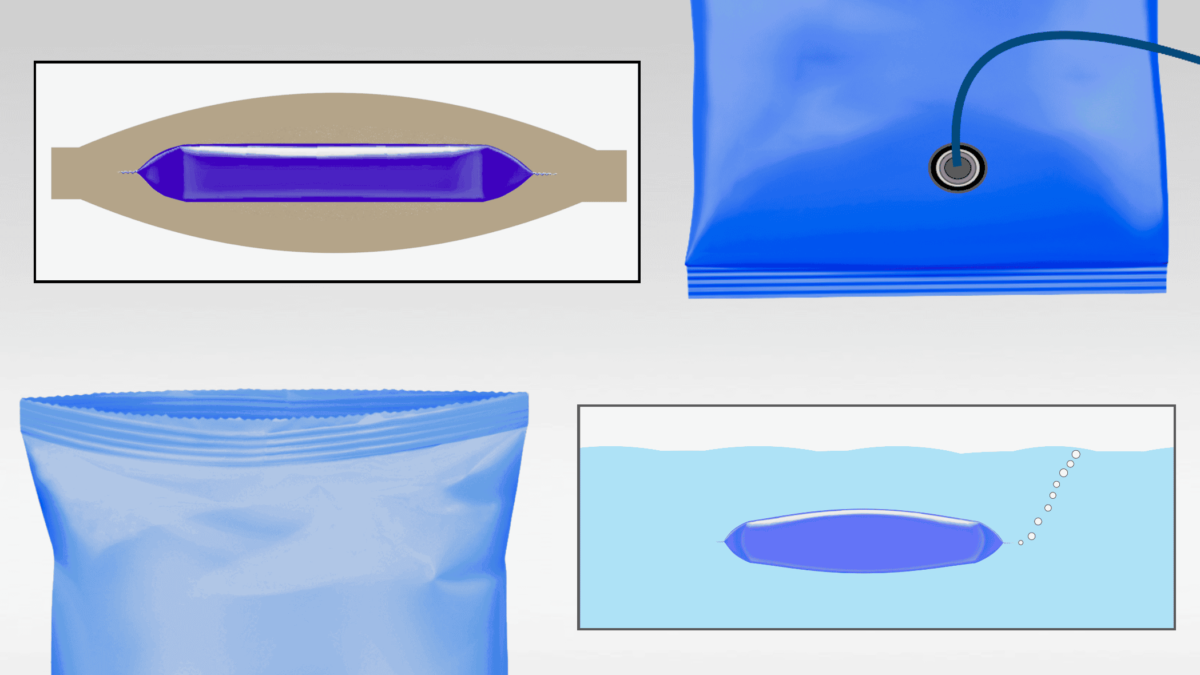

Easy Seal™️ QUICK-CHANGE Jaws also improve seal quality by providing more consistent, accurate set-ups, and through options such as Easy Seal FLEX, which helps eliminate leaks and reduce end seal fracturing by automatically compensating for extra film layers at the fin seal, and Dura-Therm material, which provides more consistent, responsive heat transfer.

Reduce Parts Costs

Easy Seal™ also reduces parts costs, since QUICK-CHANGE Jaw inserts are less expensive to replace than standard jaws.

Standardization

And Easy Seal™ creates opportunities to standardize jaw and knife designs and set-up procedures across different flow wrapper makes, models, and lines to further improve seal quality, decrease parts inventories, and reduce costs.

Greener will engineer Easy Seal™ QUICK-CHANGE Jaws to match your specific packaging requirements for heat and cold seal applications.

To learn more contact Greener Corporation. We provide integrated parts and technical services worldwide.