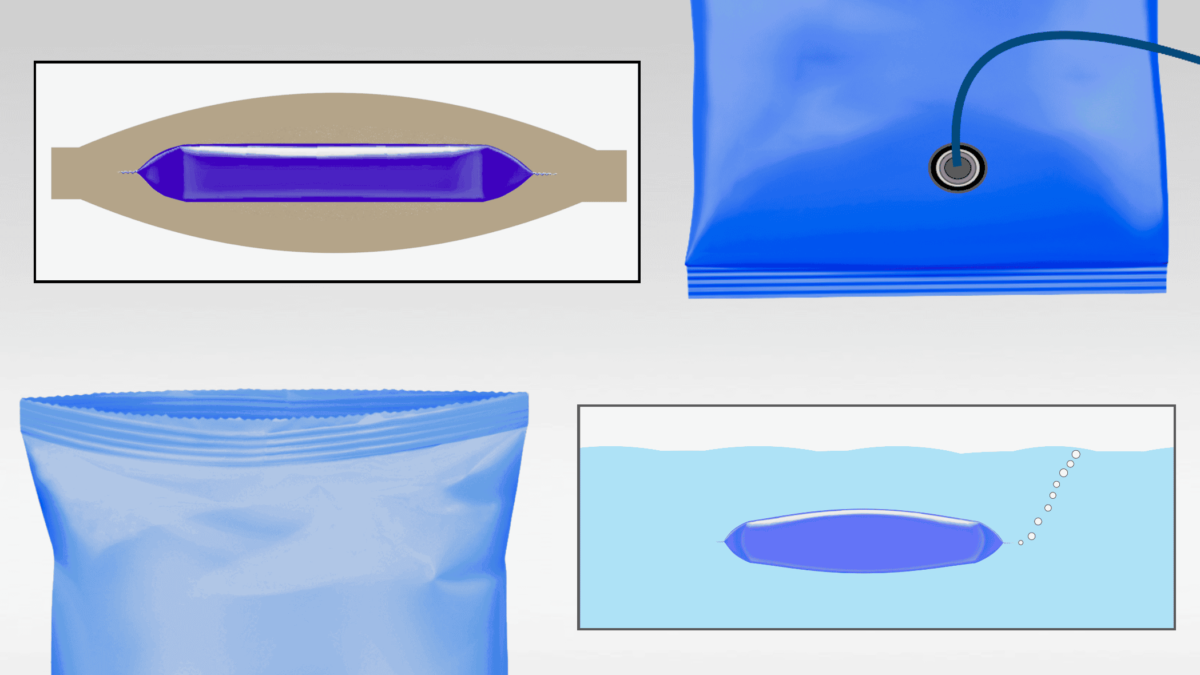

Sealing jaws on vertical baggers are not standard, universal components; they should be designed according to the unique features of your packaging operation. When you work with Greener Corporation, we integrate your machinery design and condition, packaging materials, seal integrity requirements, and other circumstances to design and manufacture sealing jaws that optimize package quality and productivity.

Customized Sealing Jaw Designs

We have developed a wide variety of sealing jaw features and will recommend customized designs that solve current packaging problems, prevent future issues, and create production efficiencies you may not have thought possible.

Serration Pattern

The serration pattern on your jaws should be designed for your packaging conditions. Greener can match your current serration profile or update serration geometry to improve results. We can recommend the optimal serration patterns for packages that require easy opening, zippers, hole punches, and other features.

Seal Reduction Profile

With our Seal Reduction Profile you can reduce seal width to decrease film costs while still maintaining and even improving seal quality.

Special Design Features

Additional design features include hole punches, tear notches, QUICK-CHANGE sealing faces, heat pipes, and special coatings.

Sealing Jaw Materials

Sealing jaw materials are also an important design factor. High durability stainless steel resists wear and damage to help maintain seal quality. Dura-Therm provides exceptional heat transfer and thermal consistency across the sealing face.

Project Development

Greener’s project development experts will help you create customized sealing jaw designs for packaging projects such as new film qualifications, changes in package size, and cross-platform sealing jaw standardization.

To learn how customized sealing jaws can improve your package quality and productivity, contact Greener Corporation. We provide integrated parts and technical services worldwide.